Definition

A Leading Industrial Heating Module Manufacturer for Precision Temperature Control Systems

refers to a specialized engineering and manufacturing partner that designs, develops, and produces compact,

high-performance heating modules capable of delivering accurate, stable, and repeatable thermal control

for industrial equipment.

Unlike conventional heating suppliers focused solely on heat output, advanced manufacturers integrate

thermal engineering, intelligent control algorithms, material science, and system-level integration

to support demanding industrial applications where temperature directly impacts quality, reliability,

and equipment lifespan.

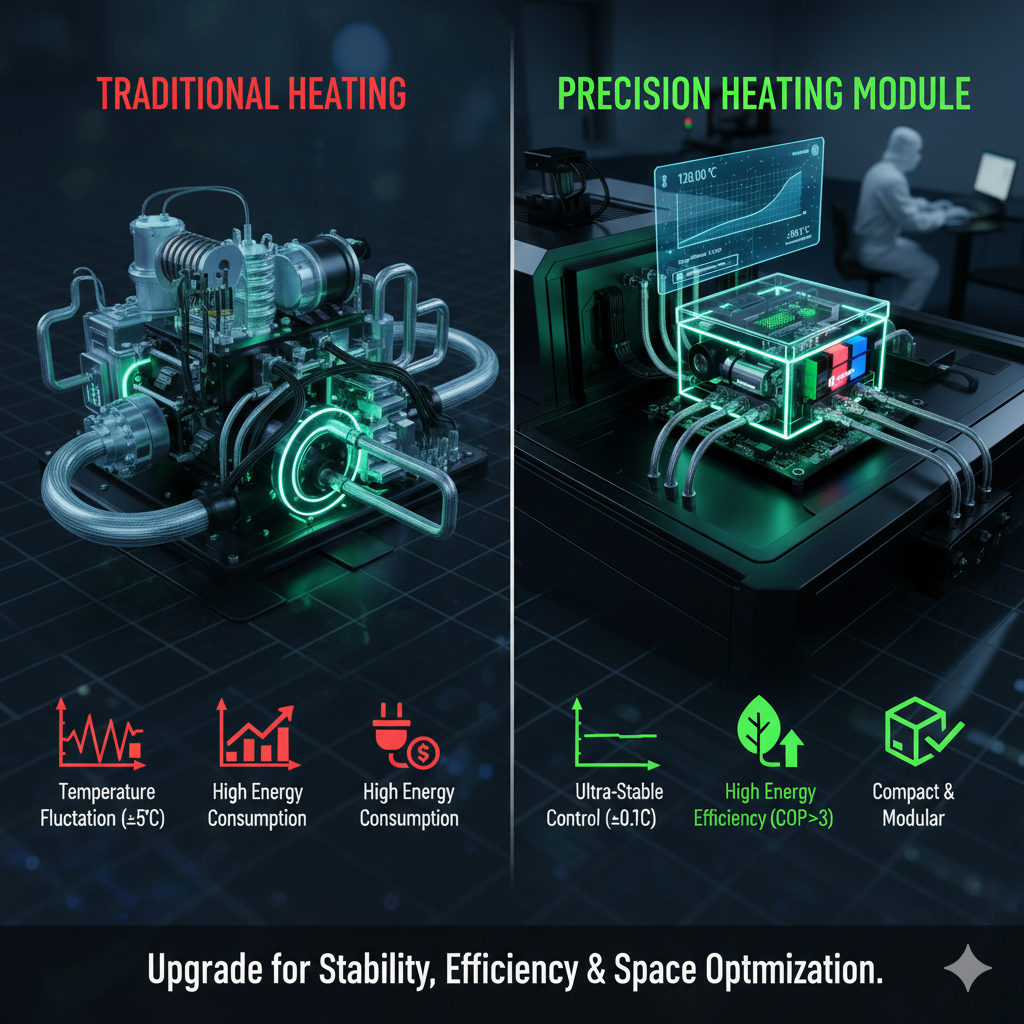

Industry Pain Points Solved

⚠ Poor Temperature Stability

Traditional heating Solutions often suffer from overshoot, undershoot, and uneven heat distribution,

leading to inconsistent process quality and higher scrap rates.

⚠ High Energy Consumption

Conventional electric heaters operate at a 1:1 energy conversion limit, resulting in excessive power

consumption during long-term industrial operation.

⚠ Integration Constraints

Bulky heating components and complex installation requirements limit OEM design flexibility

and slow product development cycles.

⚠ Slow Thermal Response

High thermal inertia in traditional systems causes delayed temperature ramp-up and poor dynamic control.

⚠ Reliability & Maintenance Issues

Frequent heater degradation and replacement increase downtime and maintenance costs.

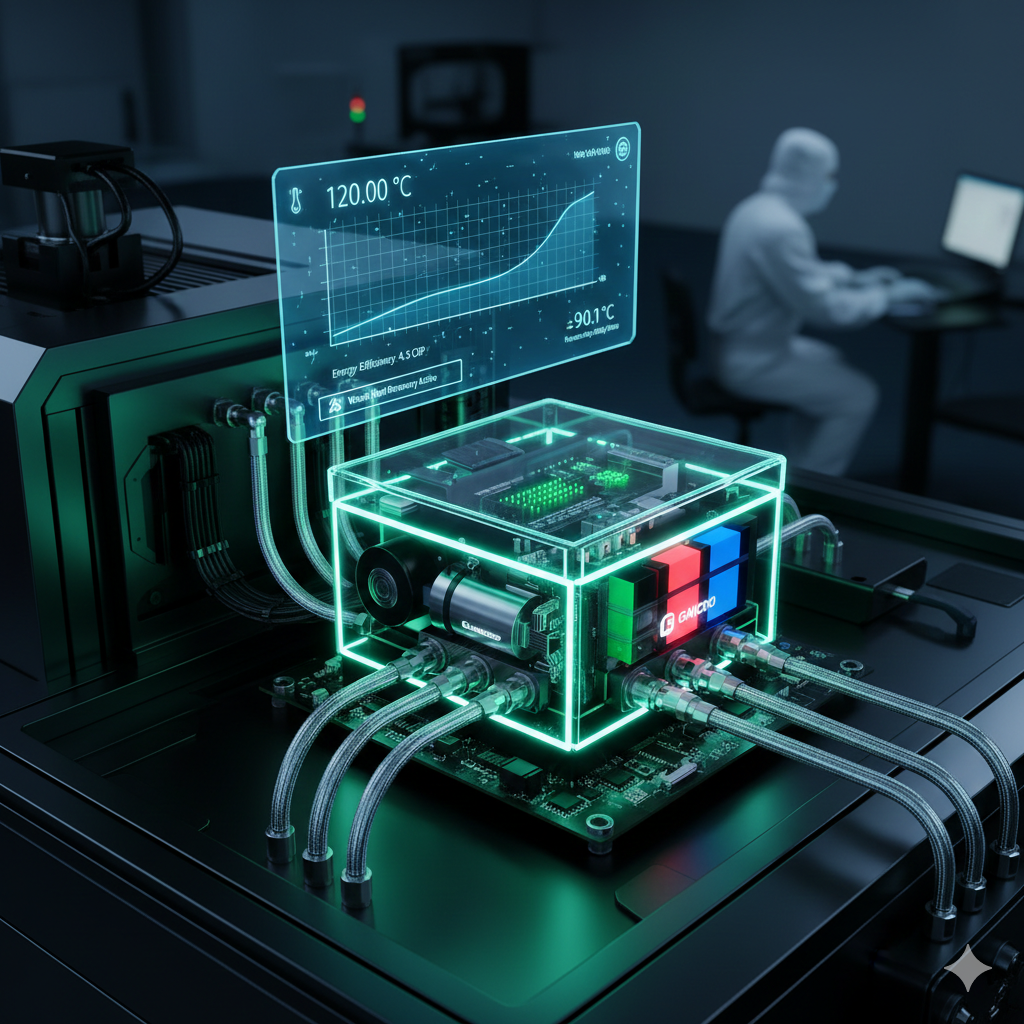

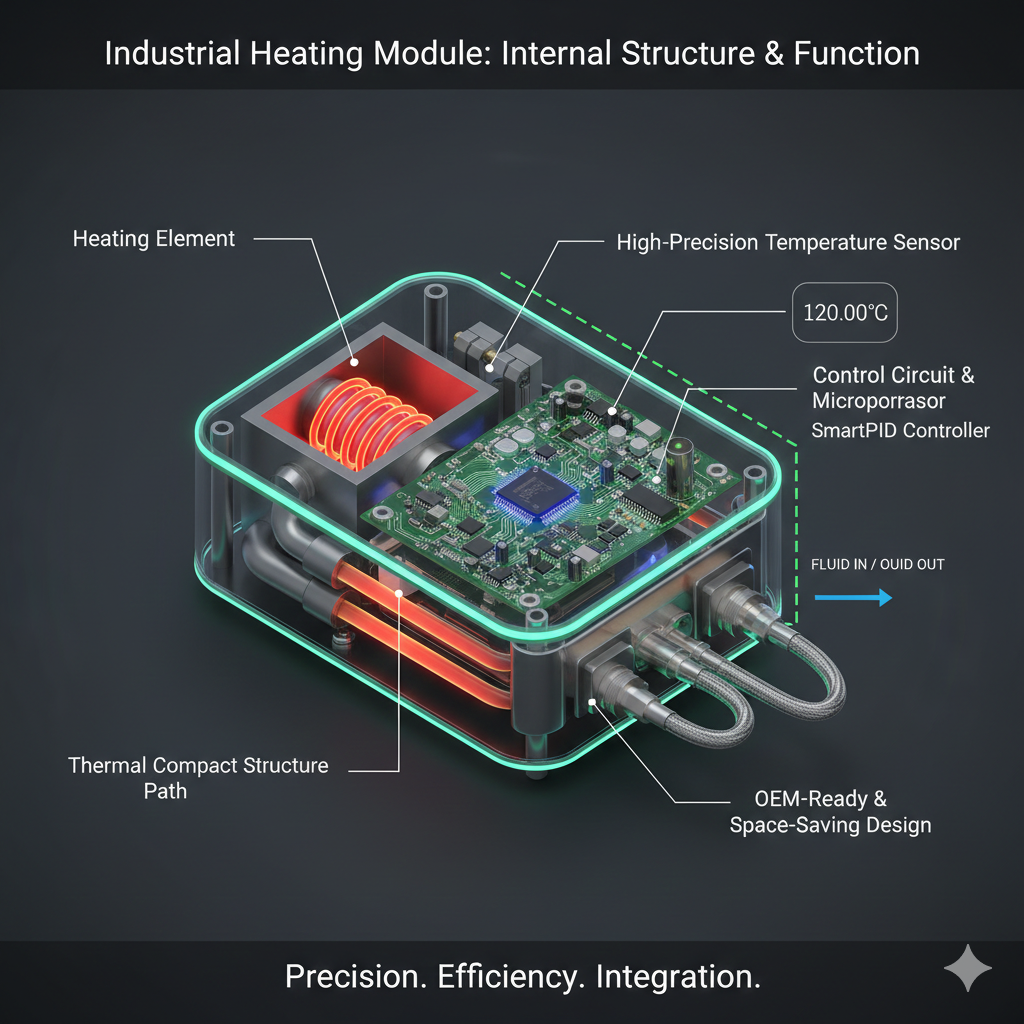

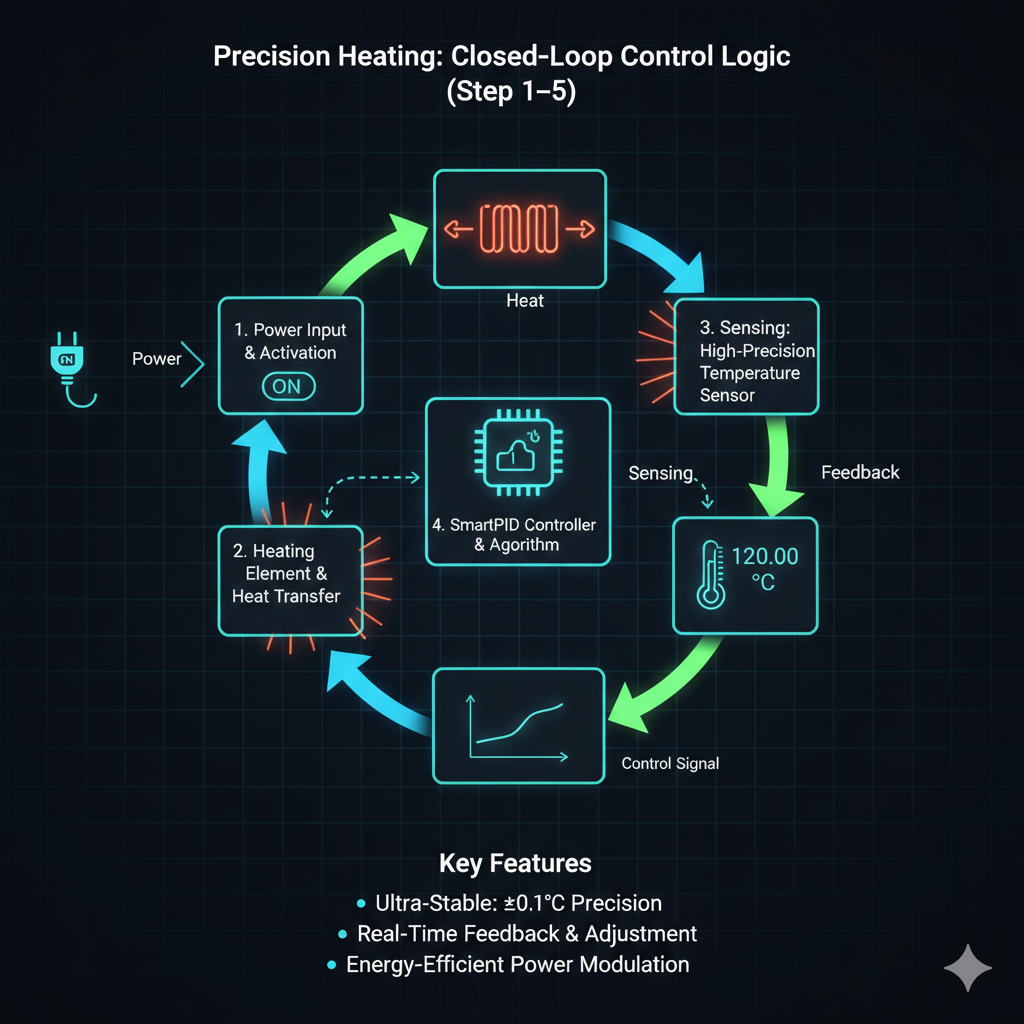

Working Principle of Precision Heating Modules

Step 1: Power Input & Regulation

Electrical power is precisely regulated through intelligent control electronics to prevent overload

and thermal stress.

Step 2: Controlled Heat Generation

Engineered heating elements generate uniform heat while minimizing localized hotspots.

Step 3: Optimized Heat Transfer

Advanced thermal interfaces ensure efficient energy transfer to the target medium.

Step 4: Real-Time Temperature Sensing

High-accuracy sensors continuously monitor system temperature conditions.

Step 5: Closed-Loop Control

PID or adaptive control algorithms dynamically adjust power output to maintain tight temperature tolerance.

Case Study: Semiconductor Equipment Application

Application Background

A semiconductor equipment manufacturer required stable thermal control for a wafer processing subsystem

operating between 70–90 °C with ±0.2 °C accuracy.

Challenges

Existing electric heaters caused slow response, uneven temperature distribution,

and excessive energy consumption.

Solution

A custom precision heating module with optimized heat transfer design, integrated sensors,

and intelligent control electronics was implemented.

Results

✔ Temperature stability improved by over 60%

✔ Energy consumption reduced by approximately 35%

✔ Equipment footprint reduced for easier OEM integration

✔ Improved process consistency and uptime

Comparison with Traditional Heating Methods

| Dimension | Precision Heating Module | Traditional Electric Heater |

|---|---|---|

| Temperature Accuracy | ±0.1–0.3 °C | ±1–3 °C |

| energy efficiency | Optimized, low loss | High consumption |

| Thermal Response | Fast | Slow |

| Integration | Compact & modular | Bulky |

Frequently Asked Questions

1. Which industries benefit most?

Semiconductors, batteries, lasers, chemical processing, and precision manufacturing.

2. How is accuracy achieved?

Through closed-loop control and real-time sensing.

3. Is OEM customization available?

Yes, including power, form factor, and interfaces.

4. Can it run continuously?

Designed for 24/7 industrial operation.

5. Does it reduce energy cost?

Yes, via efficient heat utilization.

6. Is maintenance required?

Minimal compared to traditional heaters.

7. Is it suitable for compact systems?

Yes, compact integration is a core advantage.

8. What support is provided?

Design, testing, integration, and long-term service.

Conclusion

A leading industrial heating module manufacturer for precision temperature control systems

enables industrial equipment manufacturers to achieve higher process stability, lower energy consumption,

and improved system reliability.

As industrial processes continue to demand tighter thermal tolerance and higher efficiency,

precision heating modules will remain a critical foundation of next-generation industrial thermal management.