constant temperature heating unit system overview" width="1024" height="1024" />

constant temperature heating unit system overview" width="1024" height="1024" />

Definition

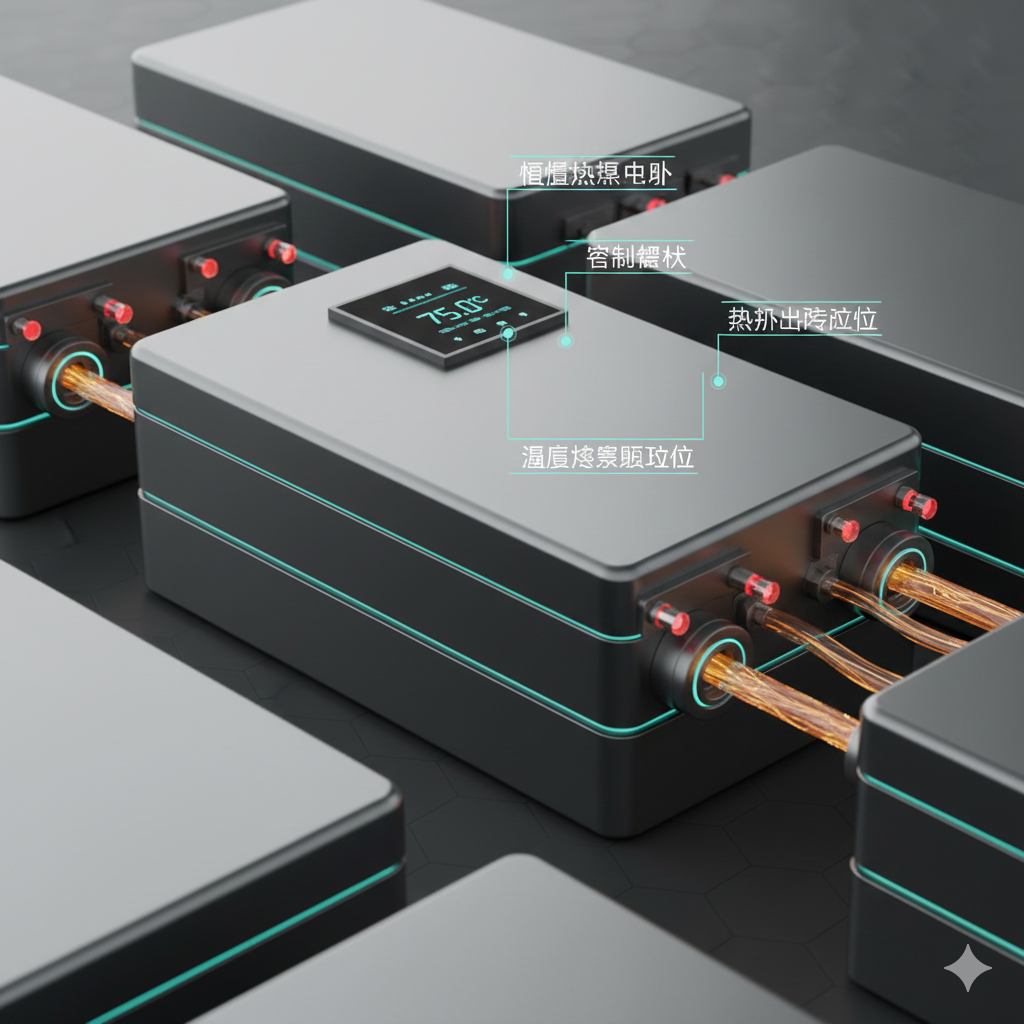

High-Performance Constant Temperature Heating Unit is an advanced industrial thermal control solution designed to maintain a predefined temperature with exceptional stability, accuracy, and repeatability.

Unlike conventional heating devices that simply generate heat, a constant temperature heating unit focuses on precise thermal regulation, ensuring temperature deviations remain within extremely tight tolerances under varying operating conditions.

These systems are widely used in semiconductor manufacturing, laser systems, laboratory instrumentation, battery processing, and advanced materials testing, where even minor temperature fluctuations directly affect process quality and system reliability.

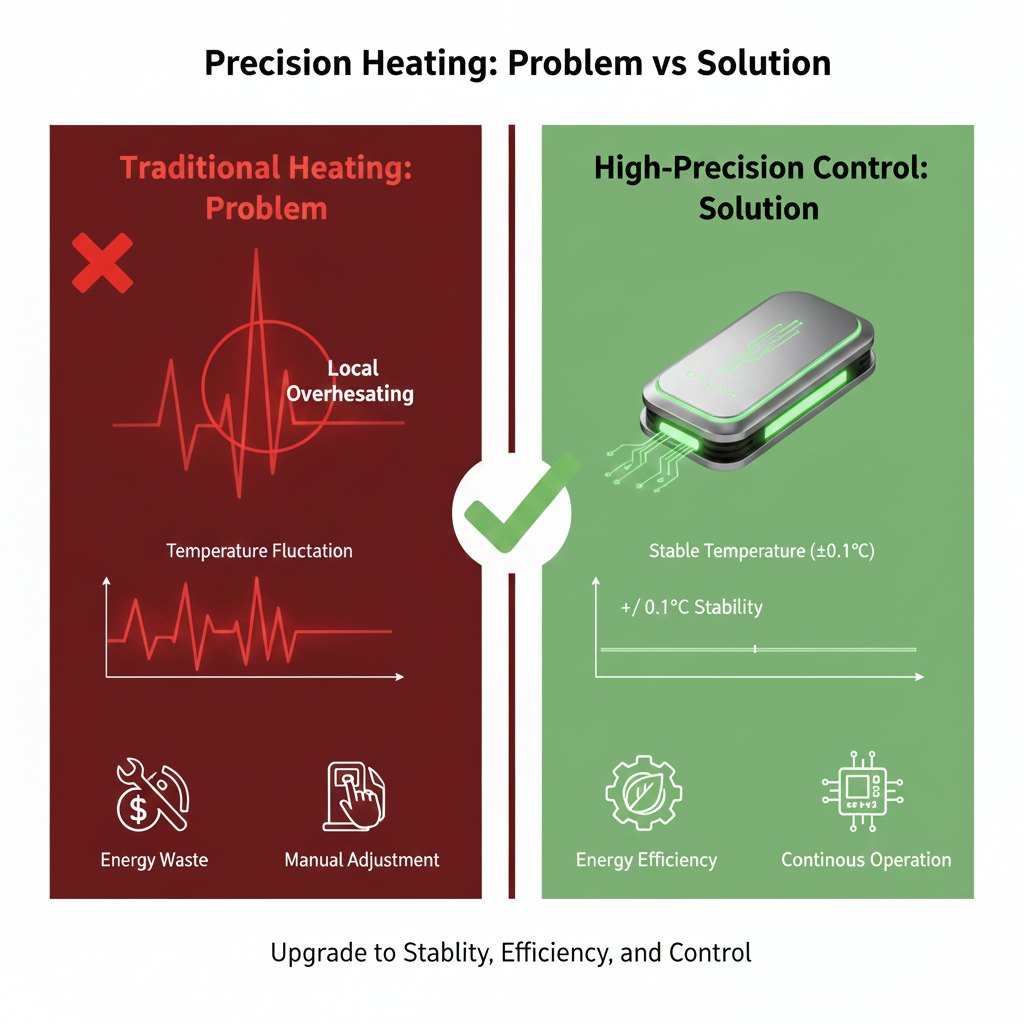

Industry Pain Points Addressed

- Temperature instability affecting process accuracy: Traditional heating Solutions suffer from oscillation and inconsistent thermal output.

- Slow thermal response: Large thermal inertia prevents rapid adaptation to changing operating conditions.

- High energy consumption: Direct electric heating leads to excessive energy usage.

- Local overheating risk: Concentrated heat causes accelerated aging and component stress.

- Limited system integration: Bulky equipment restricts compact and modular system design.

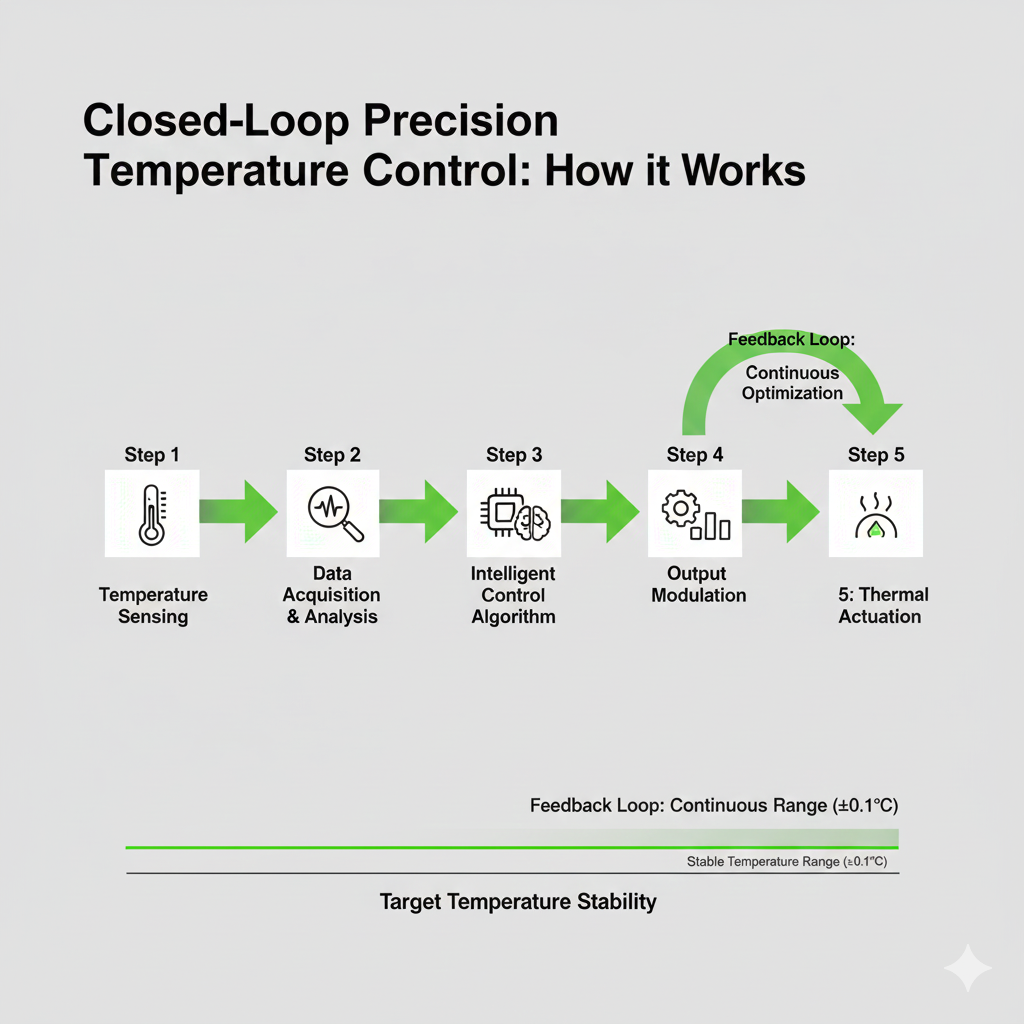

Working Principle of a Constant Temperature Heating Unit

Step 1: Temperature Sensing and Data Acquisition

High-precision temperature sensors continuously monitor key thermal points and capture spatial temperature distribution.

Step 2: Real-Time Data Processing

The control system analyzes sensor data and compares real-time temperature values with predefined targets.

Step 3: Controlled Heat Output Regulation

Heating power is modulated proportionally instead of simple on/off switching, preventing overshoot.

Step 4: Optimized Heat Distribution

Engineered heat transfer structures ensure uniform temperature across the heating zone.

Step 5: Closed-Loop Feedback Adjustment

Continuous feedback enables rapid correction and long-term stability.

Application Case Study

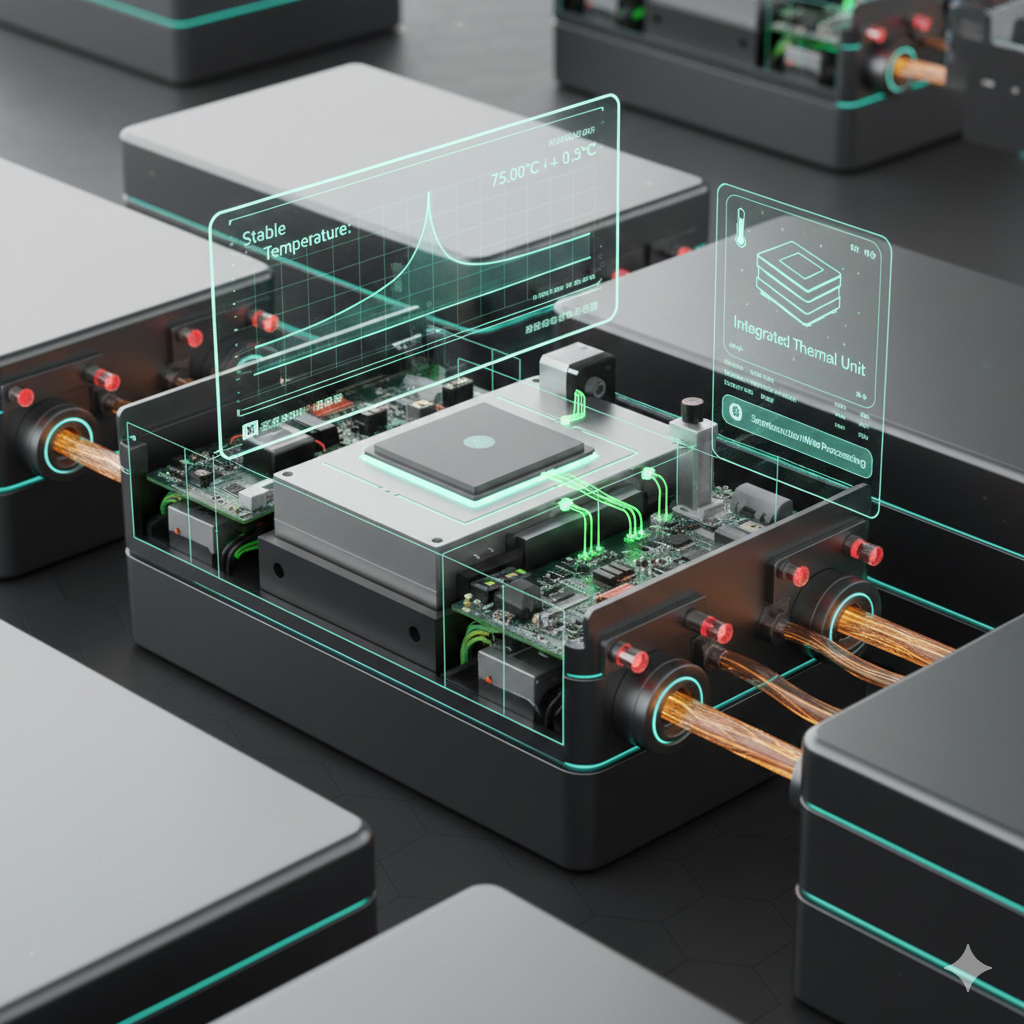

A precision optical inspection equipment manufacturer required stable temperature control at

75°C ±0.2°C during continuous operation.

After integrating a high-performance constant temperature heating unit, temperature deviation was reduced by over 60%, and total energy consumption decreased by approximately 30%.

The compact and modular design allowed seamless integration into the existing equipment enclosure while significantly improving system reliability.

Comparison with Traditional Heating Methods

| Aspect | Constant Temperature Heating Unit | Electric Heater | Hot Air / Oil Bath |

|---|---|---|---|

| Temperature Stability | ±0.1–0.3°C | ±1–3°C | Unstable |

| Response Speed | Fast | Slow | Very Slow |

| energy efficiency | High | Low | Low |

Frequently Asked Questions

Q1: Can the system run continuously? Yes, it is designed for long-term industrial operation.

Q2: Is temperature accuracy stable over time? Yes, closed-loop control ensures consistency.

Q3: Does it reduce energy consumption? Significantly, compared to traditional heaters.

Q4: Is installation complex? No, compact design simplifies integration.

Q5: Is it safe for sensitive equipment? Yes, overheating risks are minimized.

Q6: What temperature range is supported? Suitable for most precision industrial ranges.

Q7: Can it be customized? Modular designs allow customization.

Q8: Which industries benefit most? Semiconductor, laser, battery, laboratory applications.

Summary

A High-Performance Constant Temperature Heating Unit shifts industrial heating from simple energy delivery to intelligent thermal regulation.

By combining precise sensing, adaptive control, and uniform heat distribution, it delivers superior stability, reduced energy consumption, and enhanced process reliability, making it an essential solution for modern precision applications.