compact liquid temperature control system for high accuracy thermal regulation" width="1024" height="1024" />

compact liquid temperature control system for high accuracy thermal regulation" width="1024" height="1024" />

1. Definition

Compact liquid temperature control system is a specialized thermal management solution designed to precisely regulate the temperature of circulating liquids within industrial and scientific equipment.

By integrating advanced sensors, intelligent control algorithms, and high-efficiency heating or cooling modules, the system maintains liquid temperature within a very narrow tolerance range, ensuring consistent thermal conditions for precision applications.

Unlike traditional bulk heating methods, this solution delivers high accuracy, fast response, and stable continuous operation, even under variable load conditions, while its compact footprint enables seamless integration into modern industrial equipment.

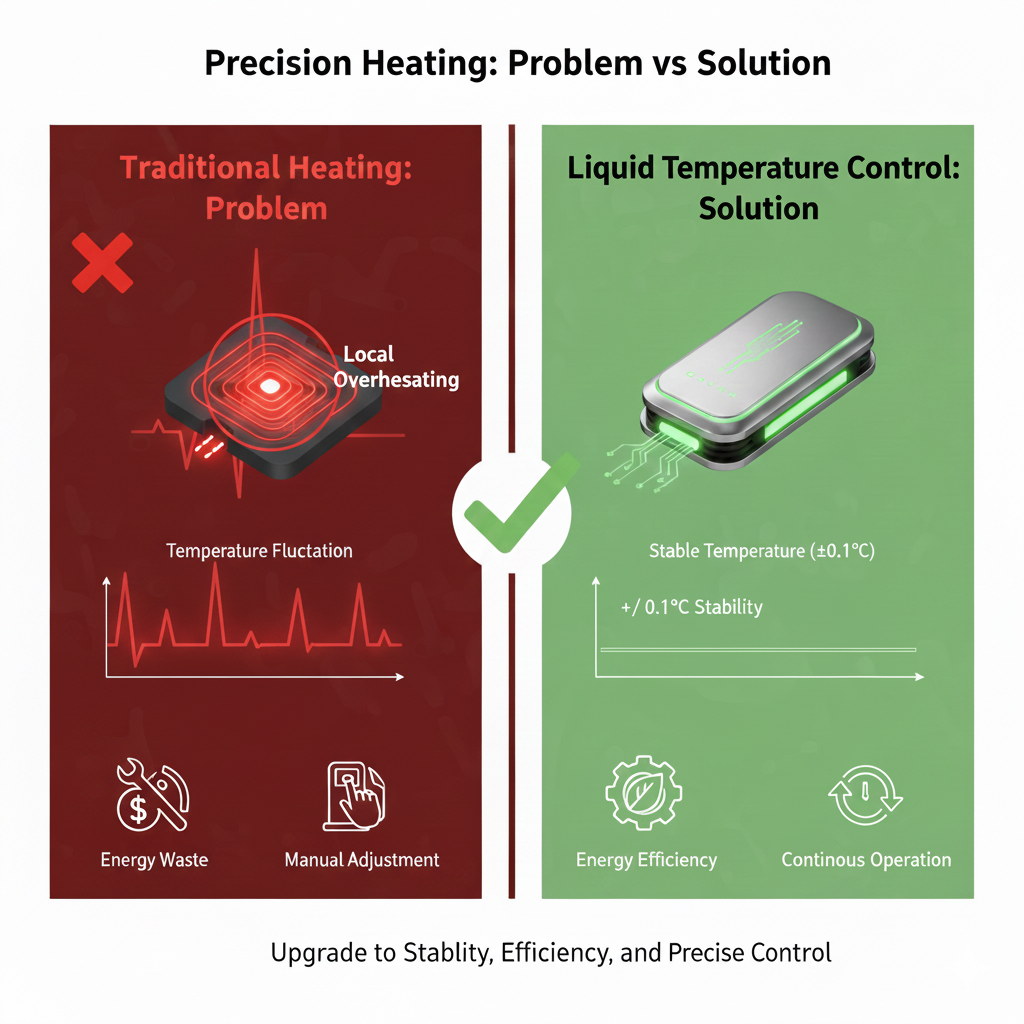

2. Industry Pain Points Addressed

Temperature Fluctuation: Conventional systems often fail to maintain stable liquid temperatures, negatively affecting product quality and process repeatability.

Slow Thermal Response: Traditional heaters respond slowly to load changes, causing overshoot and undershoot.

High Energy Consumption: Inefficient electric heating leads to excessive power usage and operational costs.

Limited Integration Flexibility: Bulky designs restrict integration into compact or modular equipment.

Operational and Safety Risks: Local overheating and unstable circulation increase maintenance and failure risks.

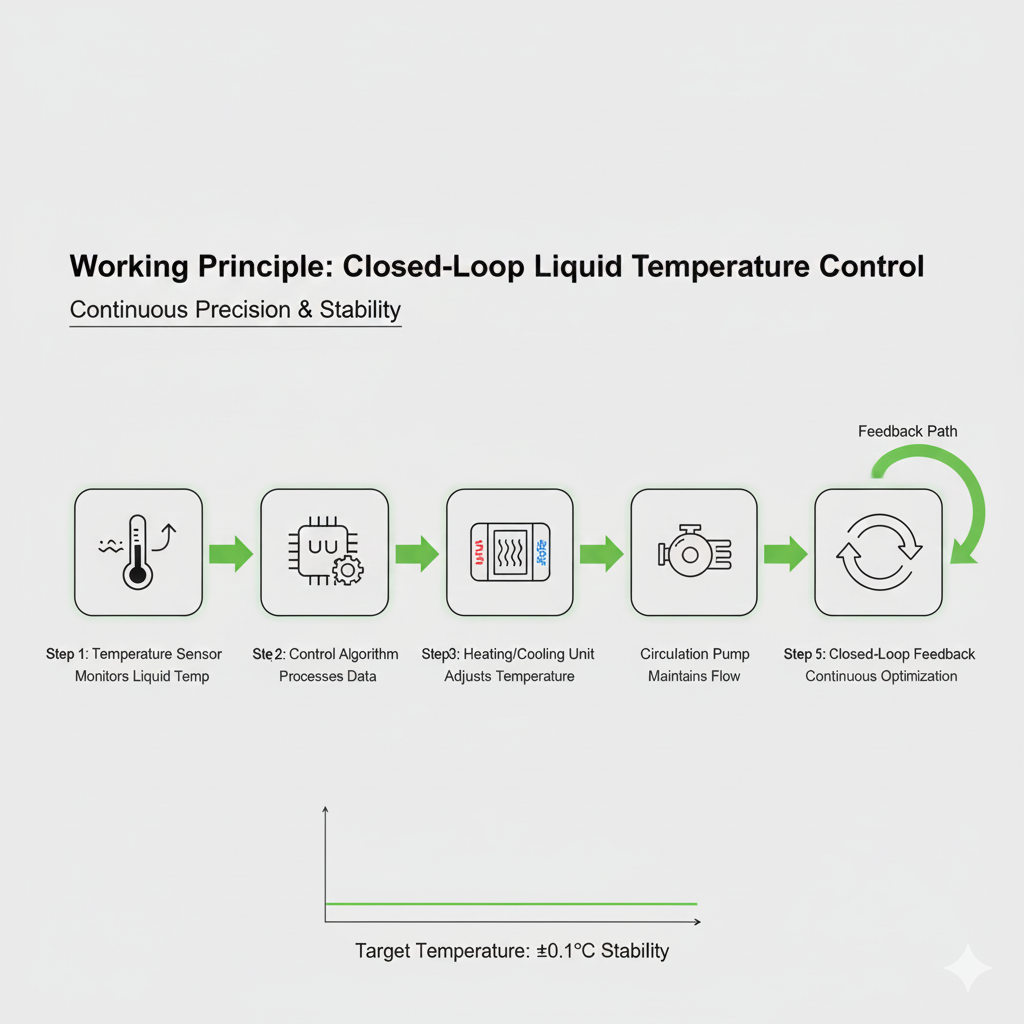

3. Working Principle

Step 1 – Real-Time Temperature Sensing: High-precision sensors continuously monitor liquid temperature at key points.

Step 2 – Intelligent Control Processing: Control algorithms compare real-time data with target setpoints.

Step 3 – Efficient Thermal Regulation: Heating or cooling output is adjusted dynamically to minimize energy waste.

Step 4 – Uniform Heat Distribution: Circulating liquid ensures homogeneous temperature distribution.

Step 5 – Continuous Feedback Optimization: Output is fine-tuned to maintain long-term temperature stability.

4. Case Study

A manufacturer of high-precision optical inspection equipment required temperature stability within ±0.2°C. Existing electric heating caused calibration drift and inconsistent measurements.

After integrating a compact liquid temperature control system, temperature stability was achieved across all operating modes. Warm-up time was reduced, energy consumption decreased by over 30%, and maintenance intervals were extended.

5. Comparison with Traditional Heating Methods

| Aspect | Compact Liquid Temperature Control System | Traditional Electric Heating |

|---|---|---|

| Temperature Accuracy | High precision, minimal fluctuation | Limited precision |

| Response Speed | Fast and adaptive | Slow |

| energy efficiency | Optimized consumption | High power usage |

| Safety | Stable and controlled | Higher overheating risk |

6. FAQ

Q1: Temperature accuracy typically reaches ±0.1–0.3°C.

Q2: Designed for continuous industrial operation.

Q3: Easily integrated into existing systems.

Q4: Compatible with water, glycol, and industrial fluids.

Q5: Reduces energy use through precise output control.

Q6: Low maintenance requirements.

Q7: Handles rapid thermal load changes.

Q8: Ideal for semiconductor, laser, lab, and medical equipment.

7. Conclusion

A compact liquid temperature control system delivers precise, stable, and energy-efficient thermal regulation while overcoming the limitations of traditional heating Solutions.

For industries requiring accuracy, reliability, and long-term stability, it represents a strategic investment in process quality and equipment longevity.