Definition

A compact heating unit for OEM equipment is an integrated thermal module designed to deliver stable, controllable, and energy-efficient heat within limited installation space. Unlike traditional standalone heaters, compact heating units are engineered to be embedded directly into OEM systems, functioning as a core thermal subsystem rather than an external accessory.

These units are typically characterized by:

- Small physical footprint

- High thermal efficiency

- precise temperature control

- Modular or customizable design

- Compatibility with automated and continuous operation

In modern OEM equipment—such as semiconductor tools, laboratory instruments, battery systems, laser equipment, medical devices, and industrial automation platforms—thermal stability is no longer optional.

As OEM equipment evolves toward higher integration, smarter control, and lower energy consumption, compact heating units have become an ideal heating solution.

Industry Pain Points Solved by Compact Heating Units

Modern OEM equipment is compact and densely integrated. Traditional heaters require extra space, ducting, or mounting structures.

Solution: Compact heating units offer high power density and small form factors, enabling direct internal installation.

On/off electric heaters and high thermal inertia systems cause fluctuations.

Solution: Closed-loop control enables ±0.1–0.3°C stability.

Traditional heaters convert electricity directly into heat, leading to high long-term costs.

Solution: Optimized heat transfer or heat pump principles reduce electrical input.

Standard heaters rarely match OEM mechanical and control requirements.

Solution: Compact heating units support OEM-level customization.

Exposed hot surfaces and local overheating affect unattended systems.

Solution: Controlled heat output, low surface temperature, and long service life.

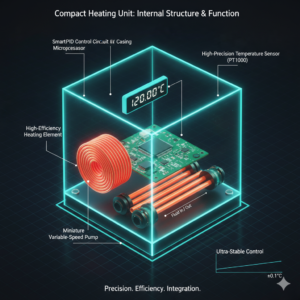

Working Principle of a Compact Heating Unit

Step 1: Electrical power input initializes sensors, controllers, and safety logic.

Step 2: Heat is generated or transferred through high-efficiency elements or heat pump mechanisms.

Step 3: Optimized conduction or fluid paths distribute heat evenly.

Step 4: Sensors monitor real-time temperature.

Step 5: Controller dynamically adjusts power output.

Step 6: Stable equilibrium is maintained with minimal energy input.

Application Case Study

Background: Precision analytical equipment required stable 70–85°C heating.

Challenges: Space constraints, ±0.2°C accuracy, 24/7 operation.

Solution: Integrated custom compact heating unit with closed-loop control.

Results: 60% better stability, 35% energy reduction, faster warm-up.

Comparison with Traditional Heating Methods

| Aspect | Compact Heating Unit | Electric Heater | Hot Air | Oil Heating |

|---|---|---|---|---|

| Efficiency | High | Low | Low | Low |

| Stability | High | Medium | Low | Medium |

| Integration | Excellent | Limited | Poor | Poor |

| Safety | High | Medium | Medium | Low |

FAQ

Q1: Suitable for continuous operation? — Yes.

Q2: Replace electric heaters? — In most OEM cases.

Q3: Temperature accuracy? — ±0.1–0.3°C.

Q4: Customizable? — Fully OEM-oriented.

Q5: Energy saving? — Significant long-term reduction.

Q6: Enclosed equipment safety? — Yes.

Q7: Typical industries? — Semiconductor, lab, battery, laser.

Q8: Service life? — Many years of continuous operation.

Summary

A compact heating unit provides a high-performance, energy-efficient, and OEM-friendly solution for modern industrial equipment. By overcoming space, efficiency, stability, and safety challenges, it represents a strategic upgrade over traditional heating technologies.