Definition

A battery preheating unit is a dedicated thermal management device designed to raise and stabilize battery temperature before operation in cold or sub-zero environments.

By actively heating battery cells to their optimal operating temperature range, the unit ensures

reliable power output, improved energy efficiency, extended battery life, and enhanced safety.

Battery preheating units are widely applied in electric vehicles (EVs), energy storage systems (ESS),

industrial battery packs, laboratory testing platforms, and mobile power equipment operating in low-temperature conditions.

Unlike passive insulation or self-heating through discharge, a battery preheating unit provides

controlled, uniform, and predictive thermal conditioning,

enabling batteries to perform consistently regardless of ambient temperature fluctuations.

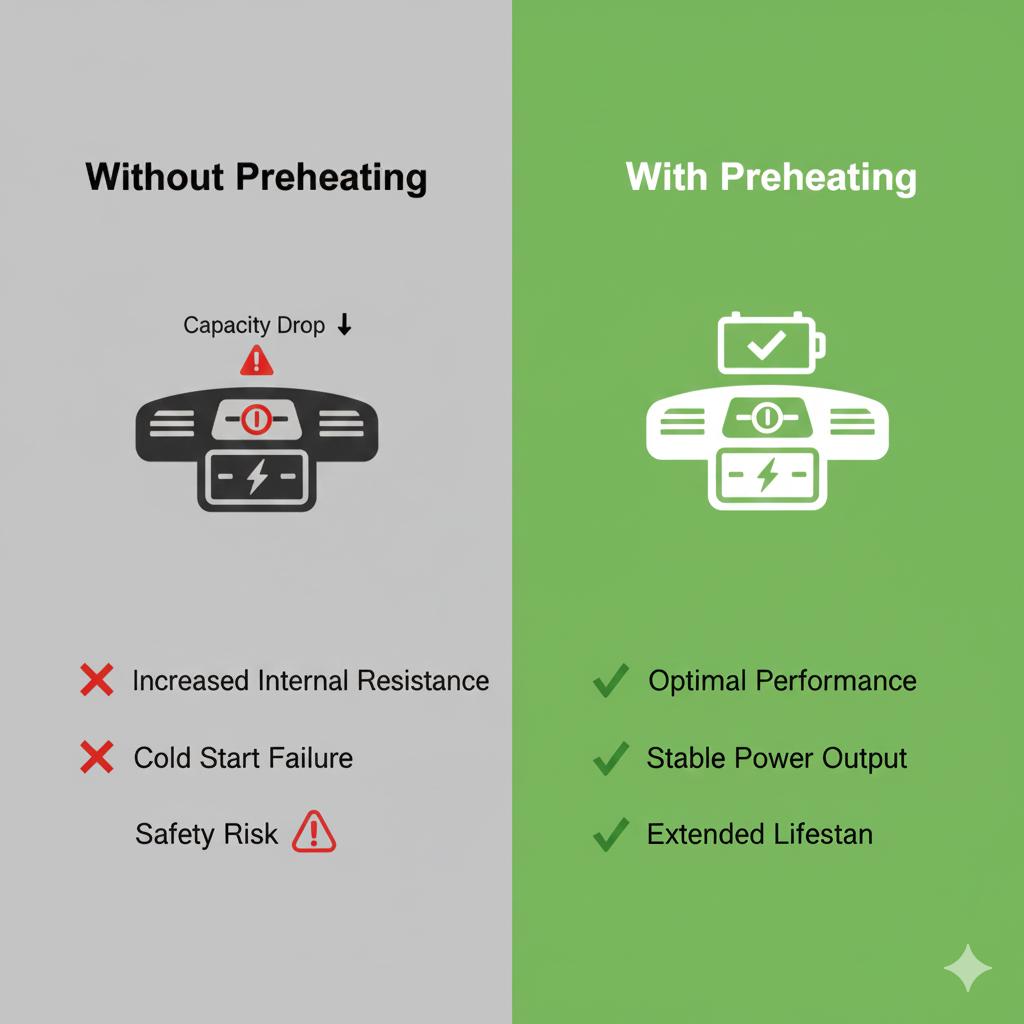

Industry Pain Points Solved

Capacity Loss at Low Temperatures

Lithium-ion and other advanced batteries suffer significant capacity degradation when operating below their optimal temperature range.

Internal resistance increases sharply, leading to reduced discharge capacity and voltage instability.

Battery Damage and Safety Risks

Charging or discharging batteries at low temperatures can cause lithium plating, internal short circuits,

and irreversible cell damage, increasing long-term safety risks.

Cold Start Instability

Cold starts result in delayed system startup, inconsistent power delivery,

and reduced efficiency for EVs, industrial systems, and energy storage platforms.

Accelerated Battery Aging

Repeated low-temperature operation accelerates degradation mechanisms,

shortening battery lifespan and increasing replacement costs.

Inefficient Traditional Heating

Conventional resistive or ambient heating methods consume excessive energy

and lack precise temperature control.

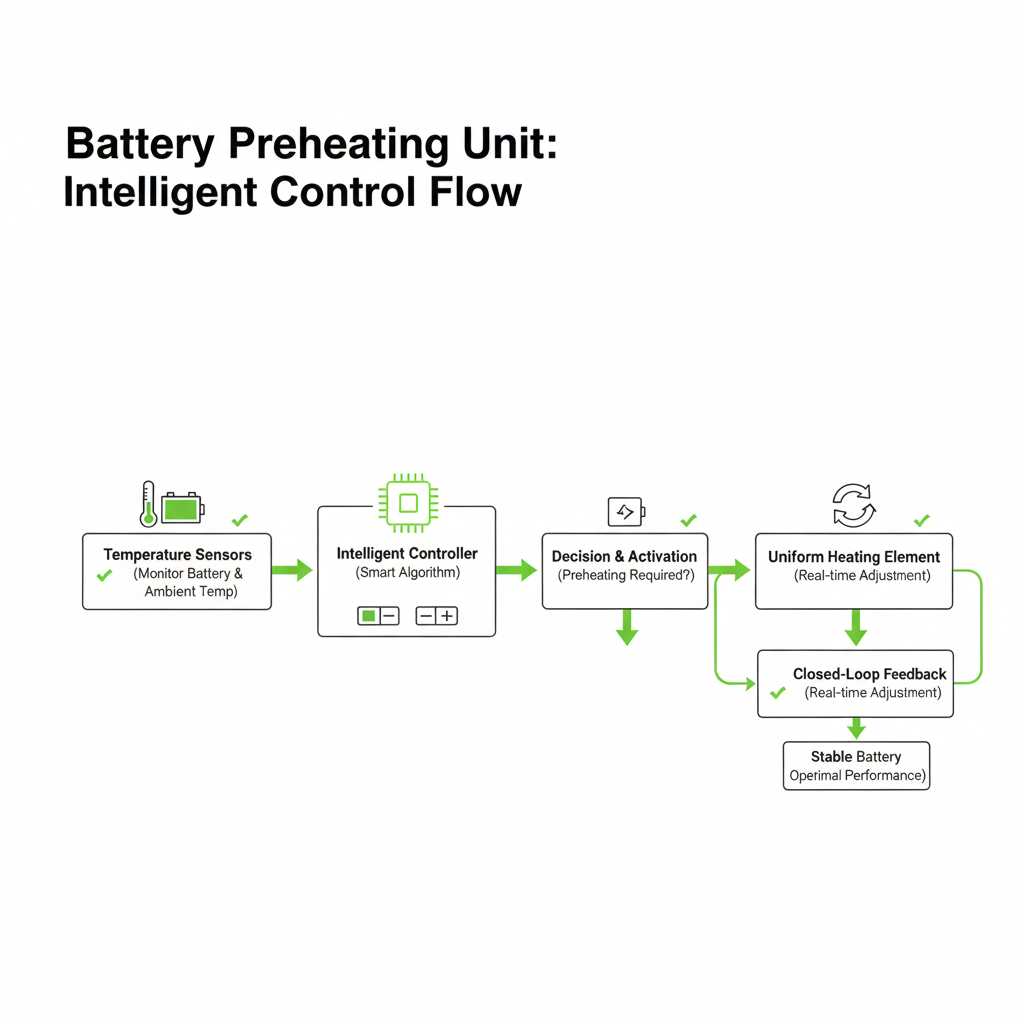

Working Principle (Step Structure)

Step 1: Temperature Detection

Integrated sensors monitor ambient and battery temperatures continuously.

When temperatures fall below the threshold, the system activates automatically.

Step 2: Intelligent Control

The controller calculates heating demand based on battery size,

chemistry, and environmental conditions.

Step 3: Uniform Heat Distribution

Controlled heat is evenly delivered across the battery pack,

preventing localized overheating.

Step 4: Closed-Loop Stabilization

Real-time feedback adjusts heating output dynamically to maintain optimal temperature.

Step 5: Transition to Normal Operation

Once target temperature is reached, heating output is reduced

and full control shifts to the BMS.

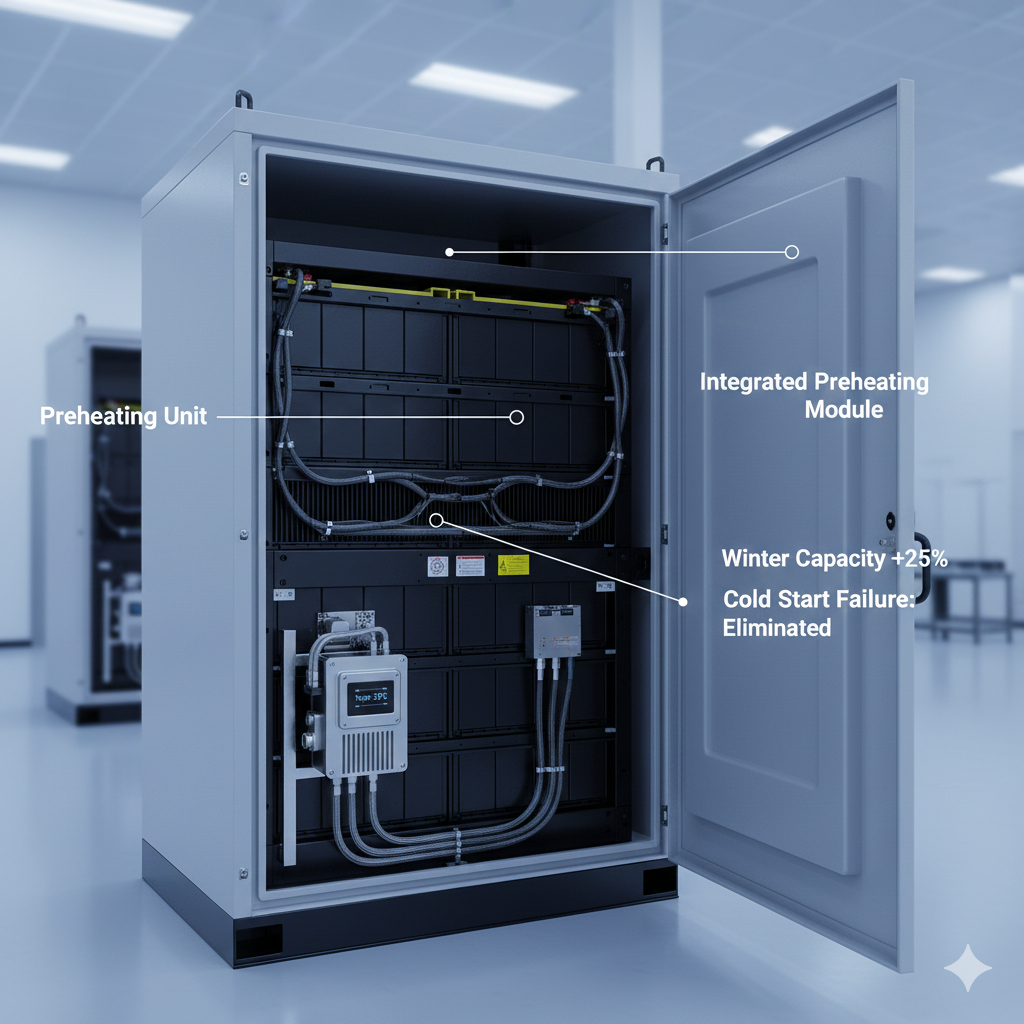

Case Study

Application Background

A grid-scale energy storage system operating in a region with winter temperatures down to -25°C.

Challenges

The system suffered from cold-start failures and more than 30% performance loss during winter.

Solution

Battery preheating units were integrated into each battery module

and activated prior to scheduled discharge cycles.

Results

- Stable operating temperature between 15°C and 25°C

- Over 25% increase in winter discharge capacity

- Elimination of cold-start failures

- Battery lifespan extended by 20–30%

- Reduced heating energy consumption

Comparison with Traditional Heating Methods

| Aspect | Battery Preheating Unit | Resistive Heater | Ambient Heating |

|---|---|---|---|

| Temperature Accuracy | High | Medium | Low |

| Energy Efficiency | High | Low | Very Low |

| Heating Uniformity | Excellent | Poor | Inconsistent |

| Safety | High | Medium | Low |

| Battery Lifespan Impact | Positive | Neutral / Negative | Negative |

FAQ

Q1: Why is battery preheating necessary in cold environments?

Low temperatures reduce capacity and increase safety risks. Preheating ensures stable operation.

Q2: Does preheating consume a lot of energy?

Modern systems are highly efficient and consume far less energy than resistive heating.

Q3: Is it compatible with different battery chemistries?

Yes, including lithium-ion and lithium iron phosphate.

Q4: Can it integrate with existing BMS?

Yes, seamless integration is supported.

Q5: Does it improve battery lifespan?

Yes, by reducing low-temperature stress.

Q6: Is long-term operation safe?

Closed-loop control ensures safe continuous operation.

Q7: How fast is the heating process?

Heating speed depends on battery size and ambient conditions.

Q8: Which applications benefit most?

EVs, ESS, industrial batteries, laboratory testing, and mobile power systems.

Conclusion

A Battery Preheating Unit for Reliable Performance in Low-Temperature Environments

is a critical component of modern battery thermal management strategies.

By addressing capacity loss, safety risks, cold-start instability, and accelerated aging,

battery preheating units ensure consistent, efficient, and safe battery performance

in demanding environments.