Starch production is an energy-intensive process involving multiple high-temperature links, such as pulping, concentration, drying, etc. High temperature heat pumps (HTHP) have broad application prospects in starch production. They can improve energy efficiency, reduce energy consumption, reduce carbon emissions, and promote the sustainable development of enterprises by recovering waste heat. Through reasonable Waste heat recovery and reuse, high temperature heat pumps not only help enterprises save operating costs, but also improve the environmental friendliness of overall production.

Main thermal energy demand in starch production

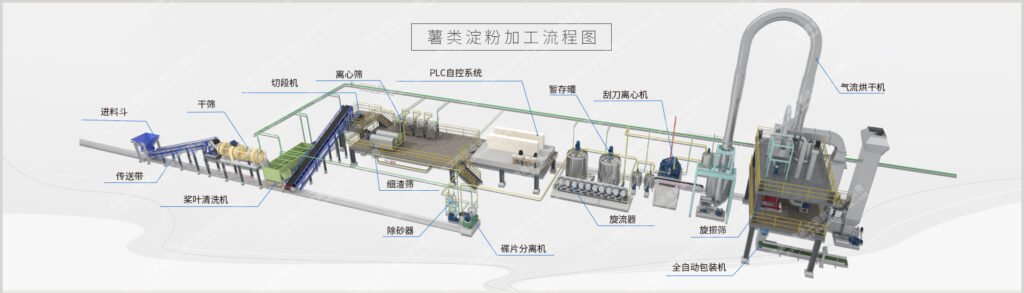

The starch production process usually includes raw material pretreatment, pulping, separation, concentration, drying and other links. Each link requires a lot of heat energy, especially in the pulping and drying process, the energy demand is particularly prominent.

- Raw material pretreatment and pulping

- Process: Raw materials (such as corn, potatoes, sugarcane, etc.) are first washed, crushed, soaked, etc., and then pulped in high temperature water or steam to fully dissolve starch granules.

- Temperature requirement: The pulping process usually requires a temperature of 80~95°C.

- Heat source demand: steam, hot water.

- Separation and Refining

- Process: After pulping, starch is separated from impurities by physical separation methods (such as centrifugation and filtration).

- Temperature requirement: The temperature of the separation process is usually 60~80°C to improve separation efficiency.

- Heat source requirement: hot water or steam.

- Concentration

- Process: The starch slurry needs to go through a concentration process to remove some water and increase the concentration of starch.

- Temperature requirement: The temperature of the concentration process is usually 90~110°C.

- Heat source requirement: steam, hot water.

- Drying

- Process: The concentrated starch slurry needs to be further dried to remove water to obtain the final powdered starch.

- Temperature requirement: During the drying process, the temperature of the hot air is usually 100~150°C, and the specific temperature depends on the type of drying equipment and production requirements.

- Heat source requirement: hot air, steam.

- Waste heat recovery

- Process: In the pulping, concentration, drying and other links, a large amount of waste heat will be generated, such as wastewater, waste gas, etc.

- Heat source demand: low-temperature waste gas (such as 60~90°C), waste water.

Application of high-temperature heat pumps in starch production

- Waste gas recovery and reuse

In the starch production process, especially in high-temperature processes such as drying and concentration, a large amount of waste gas (such as 80~120°C) will be generated. The heat contained in these waste gases is recoverable, and can be raised to a higher temperature by high-temperature heat pumps for use in other links with higher heat source demand, such as pulping and concentration.

- Application case: In the starch drying process, the waste gas temperature is 100°C. The High-temperature heat pump can heat the waste gas to 130°C for use in the pulping link, thereby reducing the demand for external energy.

- Waste water waste heat recovery

The waste water temperature in starch production is usually between 60~80°C, especially the waste water generated after the concentration and separation process. High-temperature heat pumps can recover the heat in these waste waters and raise them to the required high temperature to provide hot water or steam to support pulping, heating, concentration and other links.

- Application case: The wastewater is heated to 90°C by a high-temperature heat pump to supply the heat required for the pulping process, thereby reducing the use of gas boilers or electric heaters and reducing energy consumption.

- Providing hot water and steam

The high-temperature heat pump can recover the heat in the waste gas and wastewater, and convert it into the required hot water or steam by heating it, supplying it to the steam boiler or hot water system, and supporting various heating and concentration links in starch production.

- Application case: Assume that in the process of wastewater recovery, the temperature is raised from 70°C to 100°C and supplied to the steam boiler, which can not only reduce natural gas consumption, but also greatly improve energy utilization efficiency.

- Improve drying efficiency

The drying process in starch production requires a large amount of hot air. The high-temperature heat pump can recover the heat in the waste gas generated during the drying process, raise it to the required temperature, and supply it to the drying equipment, thereby improving the thermal efficiency of the overall production line.

- Application case: During the starch drying process, the exhaust gas temperature is 90°C, and the high-temperature heat pump can heat it to 120°C for use in the drying equipment, reducing the energy consumption of the hot air blower or steam boiler.

Advantages of high-temperature heat pumps in starch production

- Energy saving and high efficiency: High-temperature heat pumps can recover low-temperature waste heat and raise it to the required high temperature, realizing the secondary use of heat energy and avoiding energy waste.

- Environmental protection and emission reduction: By reducing dependence on traditional energy sources such as coal and natural gas, greenhouse gas emissions are reduced, helping starch production companies achieve green manufacturing and sustainable development.

- Reduce energy costs: High-temperature heat pumps reduce the demand for external energy through waste heat recovery, thereby significantly reducing energy costs in the production process.

- Improve production stability and efficiency: High-temperature heat pumps provide a stable heat source, which can ensure accurate temperature control during the production process, improve product quality and optimize production efficiency.

Case analysis: Energy saving effect of high-temperature heat pumps in starch production

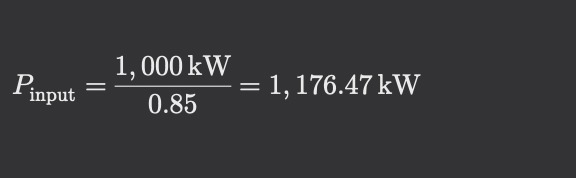

Suppose a starch production plant requires 1,000 kW of heat energy per hour to meet the heat demand of pulping, concentration and drying. Traditionally, the production line uses a gas boiler to provide heat, and the boiler efficiency is 85%. In order to meet this heat demand, the boiler needs to provide heat of:

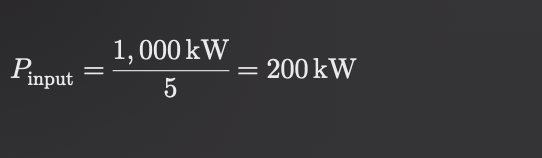

If a high-temperature heat pump is used to recover heat from waste gas and wastewater, assuming that the wastewater temperature is 70°C and the COP of the high-temperature heat pump is 5, the required electricity is:

In this way, the company saves 976.47 kW of energy consumption per hour, correspondingly reduces the fuel cost or electricity cost, and improves the economic benefits of production.

Conclusion

The application of high-temperature heat pumps in starch production provides companies with an efficient, environmentally friendly and energy-saving solution. By recovering low-temperature heat sources such as waste gas and wastewater, they can be raised to the required high temperature to meet the demand for heat energy in the production process. In this way, companies can not only significantly reduce energy consumption and operating costs, but also reduce carbon emissions, promote green production and sustainable development. With the continuous rise in energy prices and the strengthening of environmental protection policies, high-temperature heat pumps will play an increasingly important role in starch production.