Petroleum is a brown-black combustible viscous liquid extracted from deep underground and is an important liquid fossil fuel. Hydrogen is usually not produced directly from petroleum, but from Products after initial cracking of petroleum, such as naphtha, heavy oil, petroleum coke, and refinery dry gas.

Raw materials for hydrogen production from petroleum

Naphtha is one of the products of distilled petroleum. It is a light oil used as a chemical raw material produced by processing crude oil or other raw materials. It is also called crude gasoline. It generally contains 55.4% alkanes, 30.3% monocycloalkanes, 2.4% bicycloalkanes, 11.7% alkylbenzenes, 0.1% benzene, and 0.1% indanes and naphthalenes; the average molecular weight is 114, the density is 0.76g/cm3, and the explosion limit is 1.2%-6.0%. Heavy oil is the remaining heavy oil after gasoline and diesel are extracted from crude oil. It is characterized by large molecular weight and high viscosity. The relative density of heavy oil is 0.82-0.95. Its main components are hydrocarbons, and it also contains some sulfur and trace amounts of inorganic compounds.

Heavy oil contains more combustible components, including 86-89% carbon, 10-12% hydrogen, and very little other components such as nitrogen, oxygen, and sulfur.

Petroleum coke is a product obtained by thermal cracking of heavy oil. Petroleum coke is a black porous particle or block with irregular shape and size. More than 80% of the mass fraction is carbon, and the rest is hydrogen, oxygen, nitrogen, sulfur, and metal elements. It can usually be used in industries such as graphite production, smelting, and chemical industry. The cement industry is the world’s largest user of petroleum coke, and its consumption accounts for about 40% of the petroleum coke market share; secondly, about 22% of petroleum coke is used to produce prebaked anodes for aluminum smelting or graphite clicks for steelmaking. In recent years, petroleum coke has also become a realistic raw material for hydrogen production.

Naphtha hydrogen production process

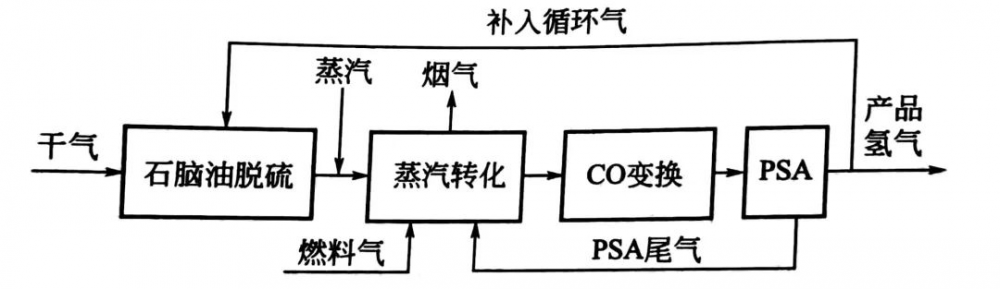

The main process of naphtha hydrogen production is naphtha desulfurization conversion, CO conversion, and PSA. Its process flow is very similar to natural gas hydrogen production. The process flow is as follows:

The High-temperature heat pump for naphtha hydrogen production is mainly used to provide 150-degree high-temperature steam in the naphtha desulfurization process, and in the cooling of PSA tail gas recovery, with a cooling temperature of 15 degrees. Compared with traditional combustion boilers, the operating cost is reduced by 30%, and carbon dioxide emissions are also reduced. The entire project can basically pay back in about 2 years.