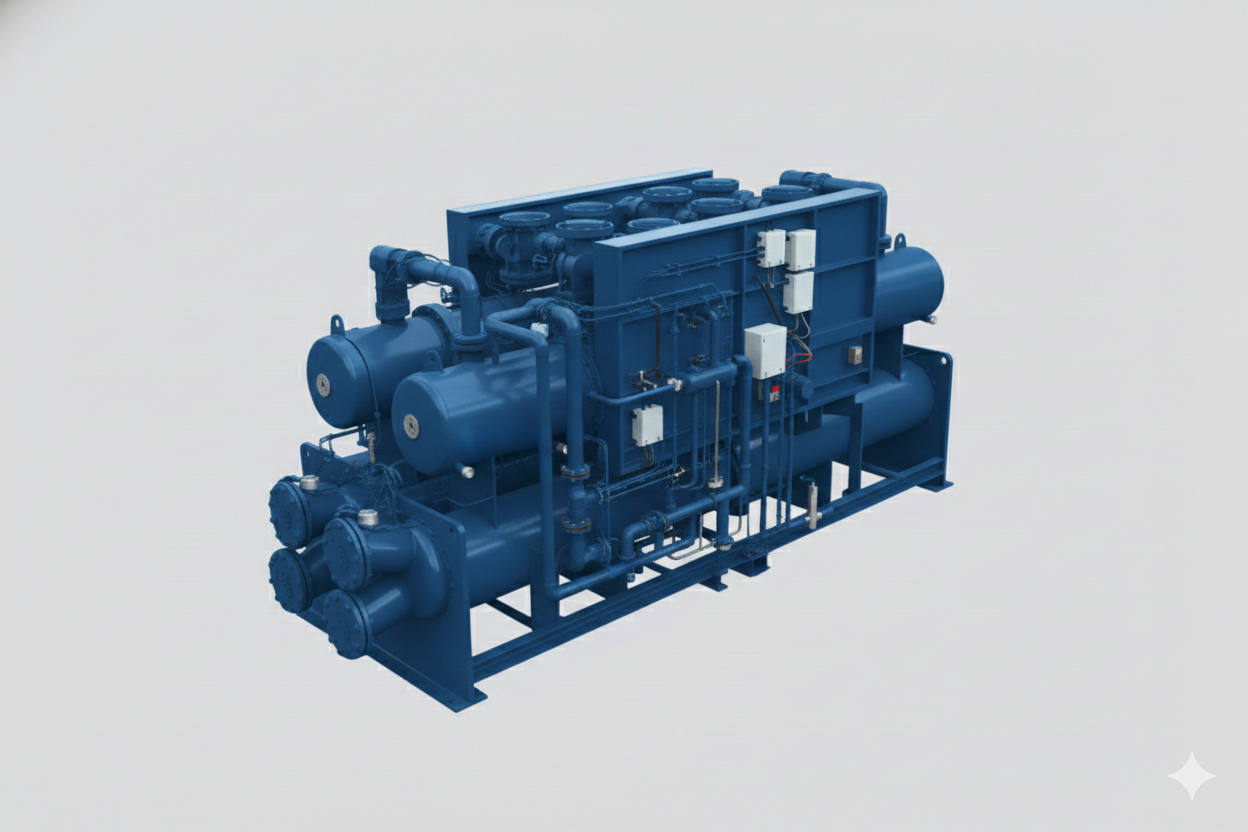

Flooded Screw Water Chiller

The flooded screw water chiller is a high-efficiency industrial cooling system designed for

medium and large cooling capacity applications. It adopts a semi-hermetic twin-screw compressor

combined with a high-efficiency shell-and-tube flooded evaporator, delivering superior heat

transfer performance, stable operation and excellent energy efficiency.

In a flooded evaporator design, the heat exchange tubes are fully immersed in liquid refrigerant,

maximizing the effective heat transfer area and significantly improving system COP. This design

is especially suitable for long-term continuous operation with high load stability requirements.

With multi-step or stepless capacity control, industrial-grade electrical components and a full

range of safety protections, the flooded screw chiller is widely used in industrial process

cooling, central cooling plants and large HVAC systems.

Applications

- Plastic injection molding, extrusion and blow molding industries

- Chemical, pharmaceutical and fine chemical process cooling

- Food & beverage processing, fermentation and cold storage systems

- Electronics manufacturing, battery and semiconductor cooling

- Central cooling systems for industrial plants and large commercial buildings

- Energy stations, district cooling and centralized HVAC systems

Technical Specifications

| Model(HARS) | 70W | 90W | 135W | 180W | 200W | 240W | 280W | 340W | 500W | 520WD | 600WD | 1000WD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Cooling Capacity (kW) | 289 | 367 | 497 | 698 | 808 | 945 | 1144 | 1407 | 1978 | 2010 | 2416 | 3956 |

| Cooling Capacity (Kcal/h ×10⁴) | 25 | 31 | 43 | 60 | 70 | 81 | 98 | 121 | 170 | 173 | 216 | 340 |

| COP | 5.9 | 6.1 | 6.0 | 6.0 | 6.2 | 6.3 | 6.2 | 6.2 | 6.0 | 6.0 | 6.0 | 6.0 |

| Refrigerant | R22 / R134a / R507 | |||||||||||

| Power Supply | 3PH 380V 50Hz | |||||||||||

| Compressor Type | Semi-hermetic twin-screw | |||||||||||

| Compressor Quantity | 1 set | 2 sets | ||||||||||

| Start Mode | Y-Δ | |||||||||||

| Capacity Control | 3-steps, 4-steps or stepless capacity control | |||||||||||

| Input Power (kW) | 49 | 60 | 83 | 116 | 131 | 150 | 184 | 228 | 329 | 335 | 402 | 652 |

| Operating Current (A) | 83 | 101 | 140 | 195 | 220 | 252 | 310 | 383 | 552 | 562 | 675 | 1095 |

| Evaporator Type | High efficiency tube and shell flooded evaporator | |||||||||||

| Chilled Water Flow (m³/h) | 50 | 63 | 85 | 120 | 139 | 163 | 197 | 242 | 340 | 345 | 432 | 680 |

| Chilled Water Pipe Connection | DN100 | DN100 | DN100 | DN125 | DN150 | DN150 | DN150 | DN200 | DN200 | DN250 | DN250 | DN300 |

| Evaporator Water Pressure Drop (kPa) | 50 | 50 | 50 | 50 | 50 | 50 | 55 | 55 | 55 | 58 | 58 | 60 |

| Condenser Type | Shell and tube | |||||||||||

| Cooling Water Flow (m³/h) | 58 | 73 | 98 | 133 | 162 | 188 | 228 | 281 | 396 | 375 | 499 | 792 |

| Cooling Water Pipe Connection | DN100 | DN100 | DN125 | DN150 | DN150 | DN150 | DN150 | DN150 | DN200 | DN250 | DN250 | DN300 |

| Condenser Water Pressure Drop (kPa) | 46 | 46 | 47 | 47 | 48 | 48 | 50 | 50 | 53 | 53 | 56 | 58 |

| Dimensions (L×W×H mm) | 3100×1200×1700 | 3100×1200×1700 | 3200×1260×1850 | 3650×1360×1990 | 3700×1550×2200 | 3700×1650×2250 | 3700×1700×2300 | 3750×1700×2500 | 3800×2200×2850 | 4850×2100×2300 | 5400×2050×2500 | 5990×2350×3050 |

| Net Weight (kg) | 2500 | 2500 | 3100 | 3500 | 3600 | 4000 | 4350 | 5800 | 7200 | 8380 | 11500 | 13550 |

Nominal working conditions: chilled water inlet/outlet temperature 17℃/12℃,

cooling water inlet/outlet temperature 30℃/35℃.

Specifications are subject to change without prior notice.