Definition: What Is a 60 degree heat pump

A 60 degree heat pump is a specialized heat pump system engineered to deliver stable hot water or thermal output at approximately 60 °C (140 °F) with high energy efficiency. Unlike conventional electric heaters that generate heat directly from electricity, a 60 degree heat pump transfers heat from ambient air, water, or waste heat sources, upgrading low-grade thermal energy into usable high-temperature output.

This temperature range is particularly important in industrial process heating, laboratory systems, OEM equipment, sanitary hot water, battery thermal management, and low- to medium-temperature manufacturing applications. At 60 °C, many industrial processes achieve the optimal balance between energy efficiency, material safety, and thermal stability.

Modern 60 degree heat pump systems integrate advanced compressors, optimized refrigerants, precision control algorithms, and compact modular designs, making them suitable for both large installations and space-constrained industrial equipment.

As industries face increasing pressure to reduce energy consumption and carbon emissions, the 60 degree heat pump has become a practical alternative to electric heaters, boilers, and oil-based heating systems.

Key Industry Pain Points Solved by a 60 Degree Heat Pump

High Energy Consumption and Rising Operating Costs

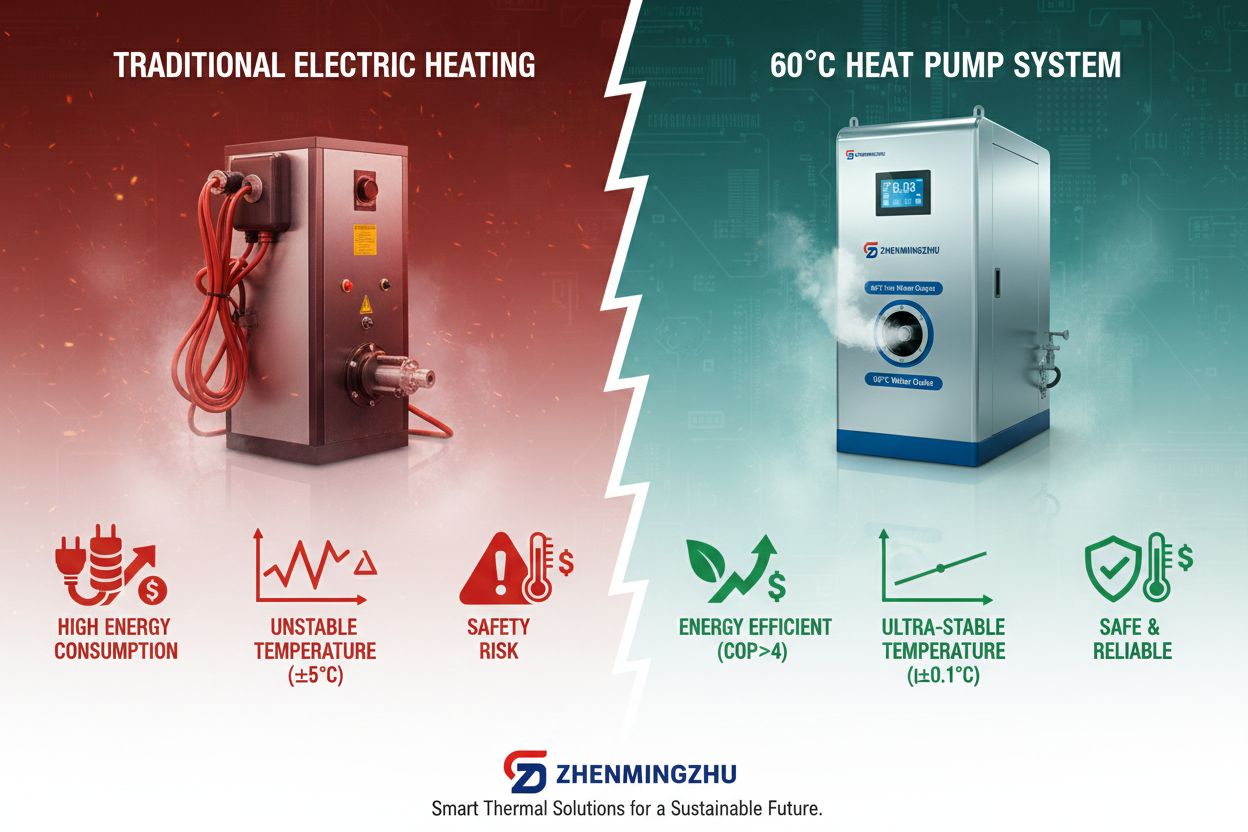

Traditional electric heaters operate with a COP close to 1. A 60 degree heat pump typically achieves a COP of 3–4, dramatically reducing electricity consumption and long-term operating costs.

Poor Temperature Stability in Process Heating

Electric heaters often cause local overheating and uneven heat distribution. A heat pump provides closed-loop temperature control, maintaining stability within ±0.3–0.5 °C.

Safety Risks from High Surface Temperatures

Electric heating elements and boilers expose operators to hot surfaces and fire risks. Heat pumps eliminate open flames and operate with lower surface temperatures.

Limited Integration for OEM Equipment

Modern 60 degree heat pumps are designed with compact, modular structures, enabling easy integration into OEM systems.

Sustainability and Carbon Reduction Pressure

By moving heat instead of generating it, heat pumps significantly reduce indirect CO₂ emissions.

Working Principle of a 60 Degree Heat Pump

Step 1: Heat Absorption (Evaporation)

Low-grade heat is absorbed from air, water, or waste heat sources.

Step 2: Compression and Temperature Lift

A high-efficiency compressor raises the refrigerant temperature to reach 60 °C output.

Step 3: Heat Release (Condensation)

Heat is transferred to water or process fluids via the condenser.

Step 4: Expansion and Cycle Reset

Pressure and temperature drop before the refrigerant returns to the evaporator.

Step 5: Intelligent Control

Sensors and control algorithms ensure stable output and fast response.

Case Study: Industrial Process Heating Upgrade

Background: A manufacturing plant required continuous 60 °C hot water for surface treatment. Electric heaters caused high costs and instability.

Solution: A custom 60 degree heat pump system was integrated into the existing loop.

Results:

- Energy consumption reduced by approximately 45%

- Temperature stability improved to ±0.4 °C

- Maintenance frequency significantly decreased

- CO₂ emissions reduced by over 30%

Comparison with Traditional Heating Methods

| Item | 60 Degree Heat Pump | Electric Heater | Gas Boiler |

|---|---|---|---|

| Energy Efficiency | COP 3–4 | ≈1 | 0.8–0.9 |

| Operating Cost | Low | High | Medium |

| Temperature Stability | High | Medium | Medium |

| Safety | High | Medium | Low |

FAQ: 60 Degree Heat Pump

Q1: Is it suitable for industrial applications?

Yes.

Q2: Can it maintain 60 °C continuously?

Yes.

Q3: How much energy can be saved?

30–60%.

Q4: Does ambient temperature matter?

Performance is optimized across ranges.

Q5: Is installation complex?

No, systems are modular.

Q6: Maintenance requirements?

Low.

Q7: Is it environmentally friendly?

Yes.

Q8: Can it be customized for OEM systems?

Yes.

Conclusion

The 60 degree heat pump delivers a powerful combination of energy efficiency, safety, and temperature stability. It effectively replaces traditional electric and combustion-based heaters while reducing operating costs and carbon emissions.

For industrial users seeking reliable 60 °C heating with long-term sustainability, a 60 degree heat pump is a strategic investment in future-ready thermal management.