1. Definition of Micro High Temperature Heat Pump

Micro high temperature heat pump refers to a compact, highly integrated thermal system designed to deliver high-temperature output (typically 80°C–160°C or higher) within a minimal physical footprint.

Unlike conventional heat pumps intended for space heating or low-temperature applications, this solution is engineered specifically for precision industrial heating where energy efficiency, space optimization, and thermal stability are critical.

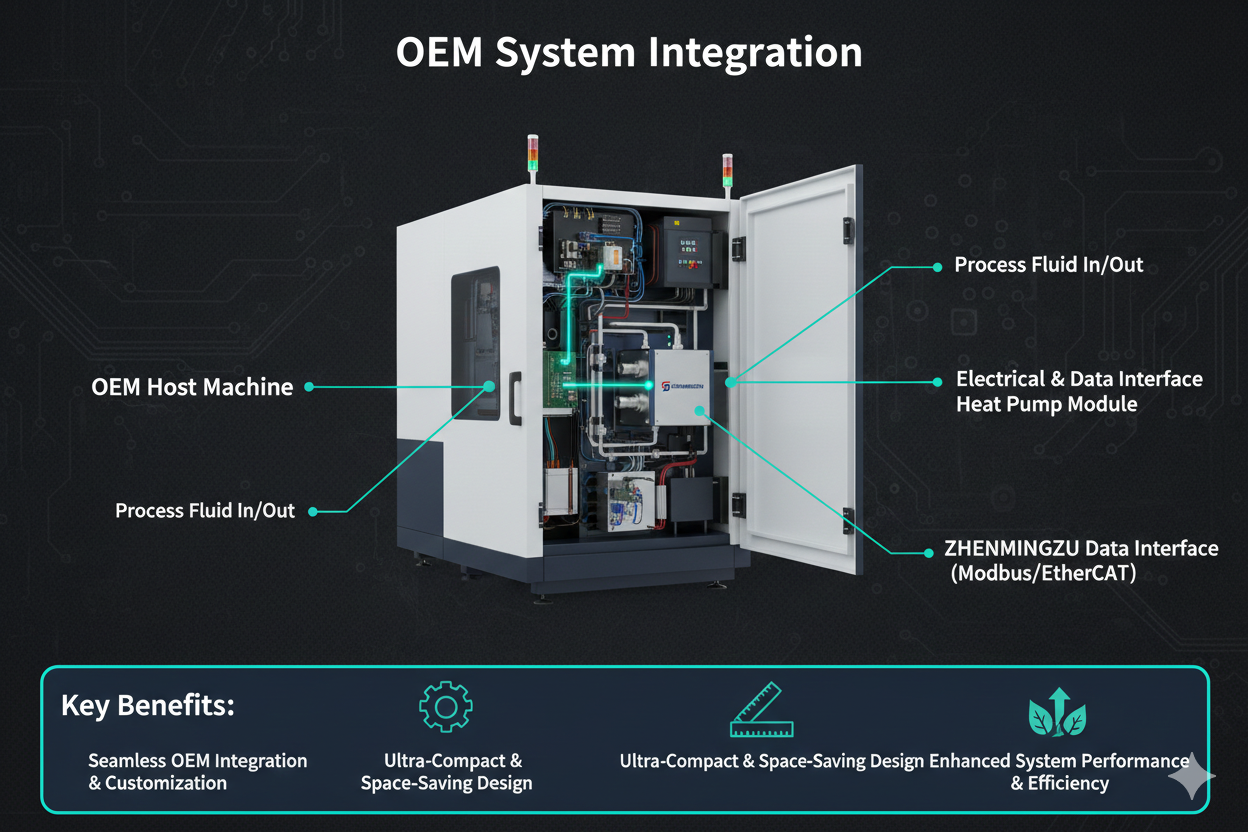

Key characteristics include:

- Compact modular structure for OEM integration

- Advanced compressors for elevated temperature lift

- High-density heat exchangers

- Intelligent digital temperature control

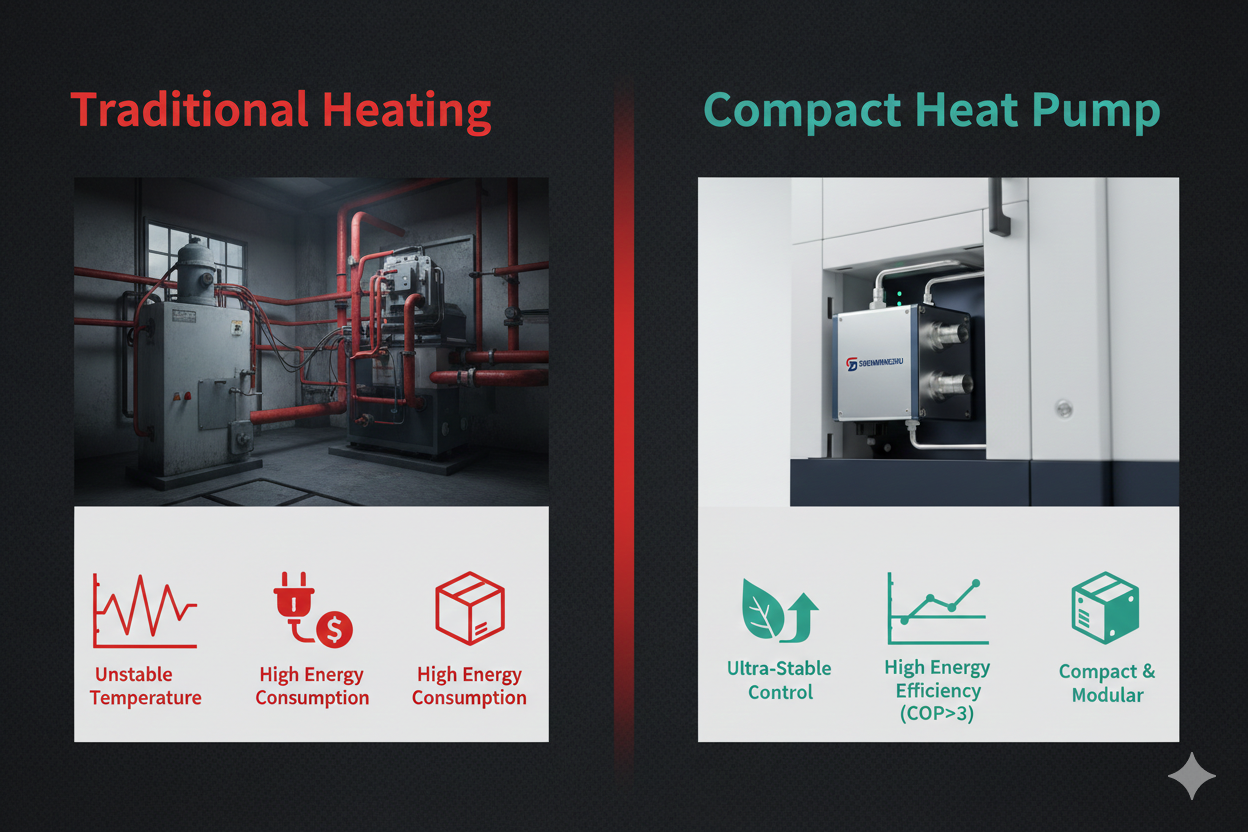

2. Industry Pain Points Solved

① Limited Installation Space

Traditional boilers and resistance heaters require bulky infrastructure. A micro high temperature heat pump delivers high output in a compact form, ideal for modern OEM equipment.

② High Energy Consumption

Electric resistance heating consumes energy at a 1:1 ratio. Heat pump technology multiplies energy efficiency through thermal transfer.

③ Unstable Temperature Control

Conventional heating systems suffer from thermal inertia. Micro heat pumps offer closed-loop control with rapid response.

④ Carbon Emission Pressure

Electrification and sustainability regulations drive industries away from fossil fuel systems.

⑤ OEM Customization Limitations

Standard heaters lack flexibility. Micro systems are easily customized for size, temperature range, and control interfaces.

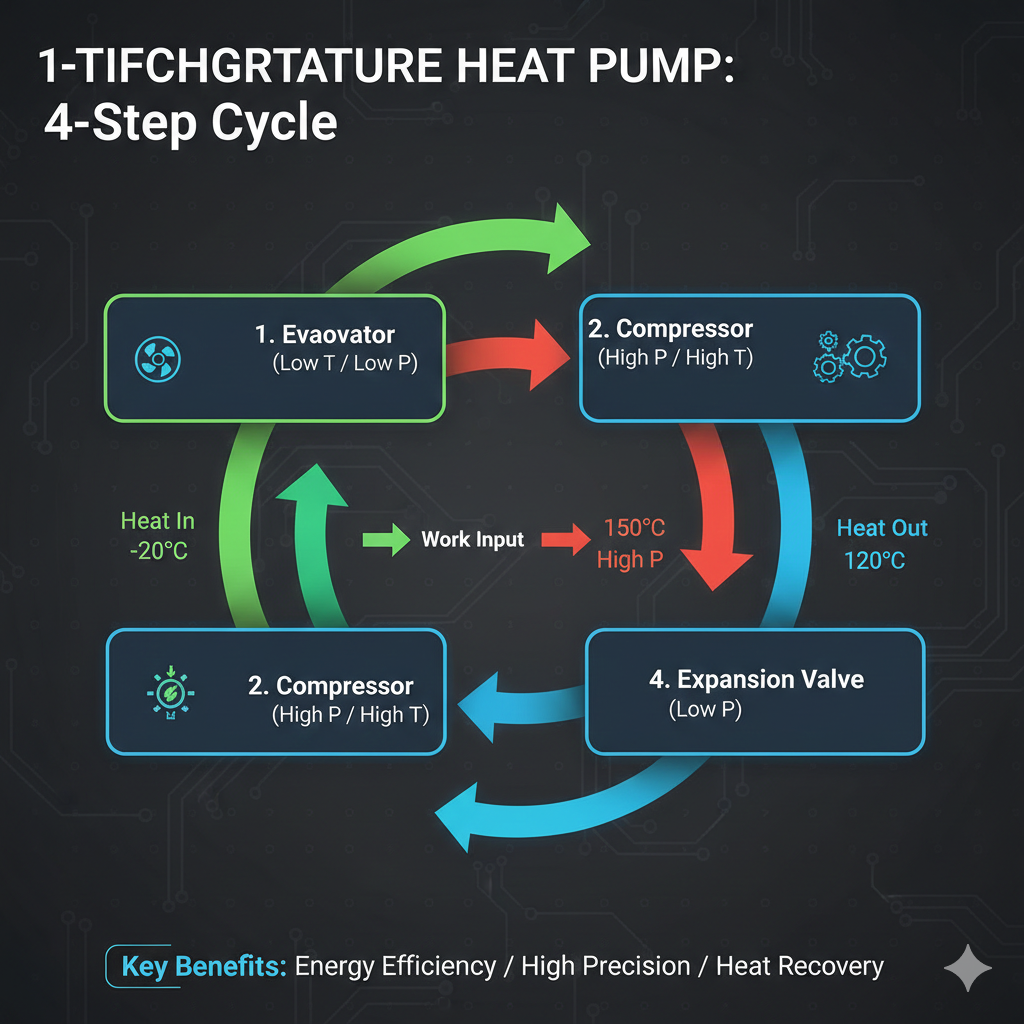

3. Working Principle of Micro High Temperature Heat Pump

Step 1: Heat Absorption

Low-grade heat is extracted from air, water, or industrial waste heat sources.

Step 2: High-Temperature Compression

A specialized compressor elevates the refrigerant temperature to industrial-grade levels.

Step 3: Heat Release

Thermal energy is transferred through a compact condenser to the target process.

Step 4: Expansion & Cycle Reset

The refrigerant pressure drops and the cycle repeats continuously.

✔ Intelligent Control: Integrated sensors and PID algorithms ensure ±0.3°C accuracy.

high temperature heat pump system" width="1024" height="1024" />

high temperature heat pump system" width="1024" height="1024" />

4. Industrial Application Case Study

Application: Precision manufacturing equipment requiring 120°C constant heat

Challenges:

- Limited installation space

- High electricity consumption

- Unstable temperature using electric heaters

Solution:

A custom micro high temperature heat pump integrated directly into the OEM system frame.

Results:

- 40% reduction in energy consumption

- ±0.3°C temperature stability

- 50% footprint reduction

- Extended maintenance cycle

5. Comparison with Traditional Heating Methods

| Aspect | Micro High Temp Heat Pump | Electric Heater | Gas / Thermal Oil |

|---|---|---|---|

| Energy Efficiency | High (COP > 2.5) | Low (≈1.0) | Medium |

| Operating Cost | Low | High | High |

| Temperature Accuracy | Very High | Medium | Medium |

| System Size | Compact | Compact | Large |

6. Frequently Asked Questions

Q1: What temperature range is supported?

A: Typically 80°C–160°C, customizable for higher ranges.

Q2: Can it operate continuously?

A: Yes, designed for 24/7 industrial duty.

Q3: Is it suitable for OEM integration?

A: Fully customizable for OEM systems.

Q4: Can it replace electric heaters?

A: In most industrial scenarios, yes.

Q5: Does it support Waste heat recovery?

A: Yes.

Q6: What about maintenance?

A: Lower than traditional heating systems.

Q7: Is it environmentally friendly?

A: Significantly reduces carbon emissions.

Q8: Is customization available?

A: Yes, size, control, and temperature can be tailored.

7. Conclusion

The micro high temperature heat pump represents a new standard in industrial heating by combining compact design, superior energy efficiency, precise temperature control, and sustainability.

For OEM manufacturers and industrial users seeking high-performance heating in limited space, this solution delivers long-term economic and environmental value.