high precision temperature control system architecture for industrial equipment" width="1024" height="1024" />

high precision temperature control system architecture for industrial equipment" width="1024" height="1024" />

Definition

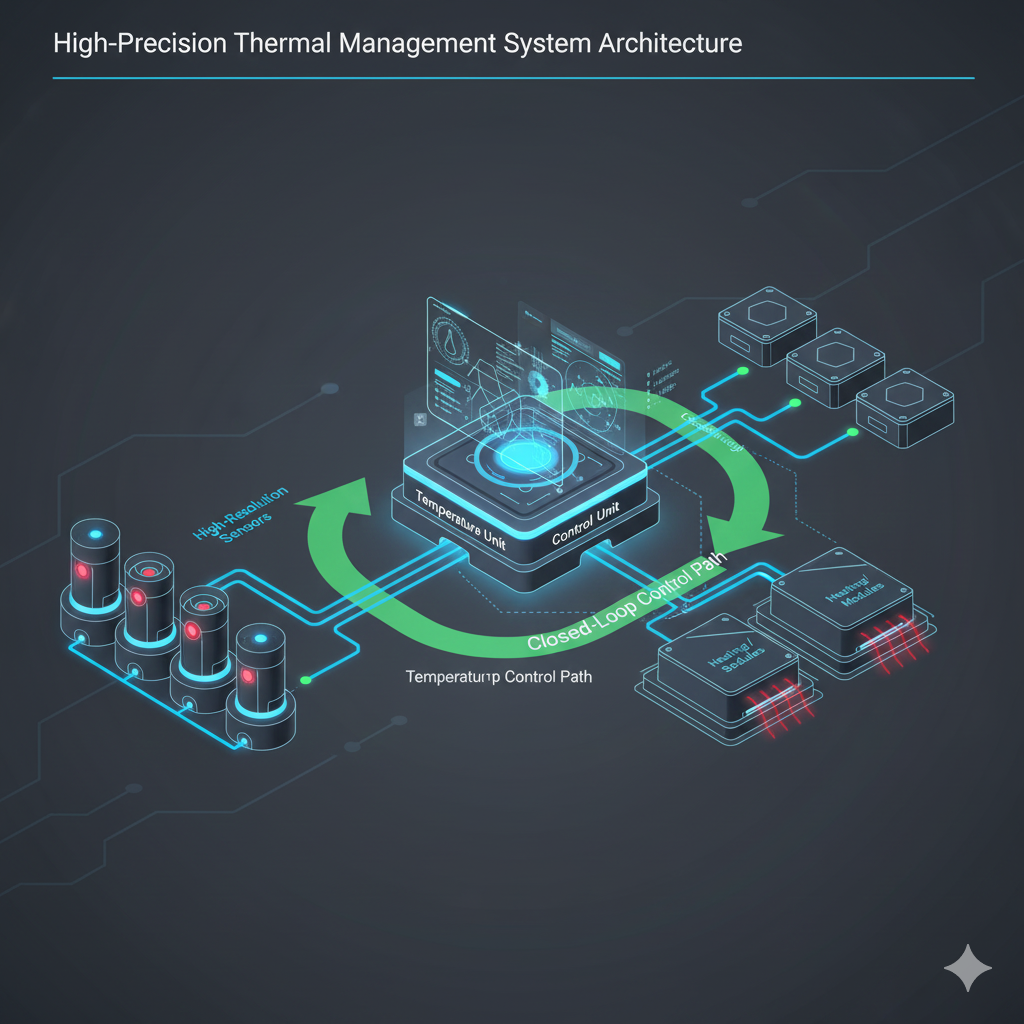

An Advanced High Precision Temperature Control System is an engineered thermal regulation solution designed to maintain, adjust, and stabilize temperature within extremely tight tolerances across modern industrial equipment.

Unlike conventional heating or cooling methods that rely on simple on/off logic or coarse control ranges, high precision temperature control systems integrate advanced sensors, intelligent control algorithms, and highly responsive heating or thermal transfer technologies to ensure consistent temperature stability under dynamic operating conditions.

In industries such as semiconductors, laser processing, battery manufacturing, laboratories, and pharmaceuticals, even minimal temperature deviations can lead to process instability, yield loss, or equipment degradation. This system serves as a core thermal infrastructure enabling accuracy, efficiency, and long-term reliability.

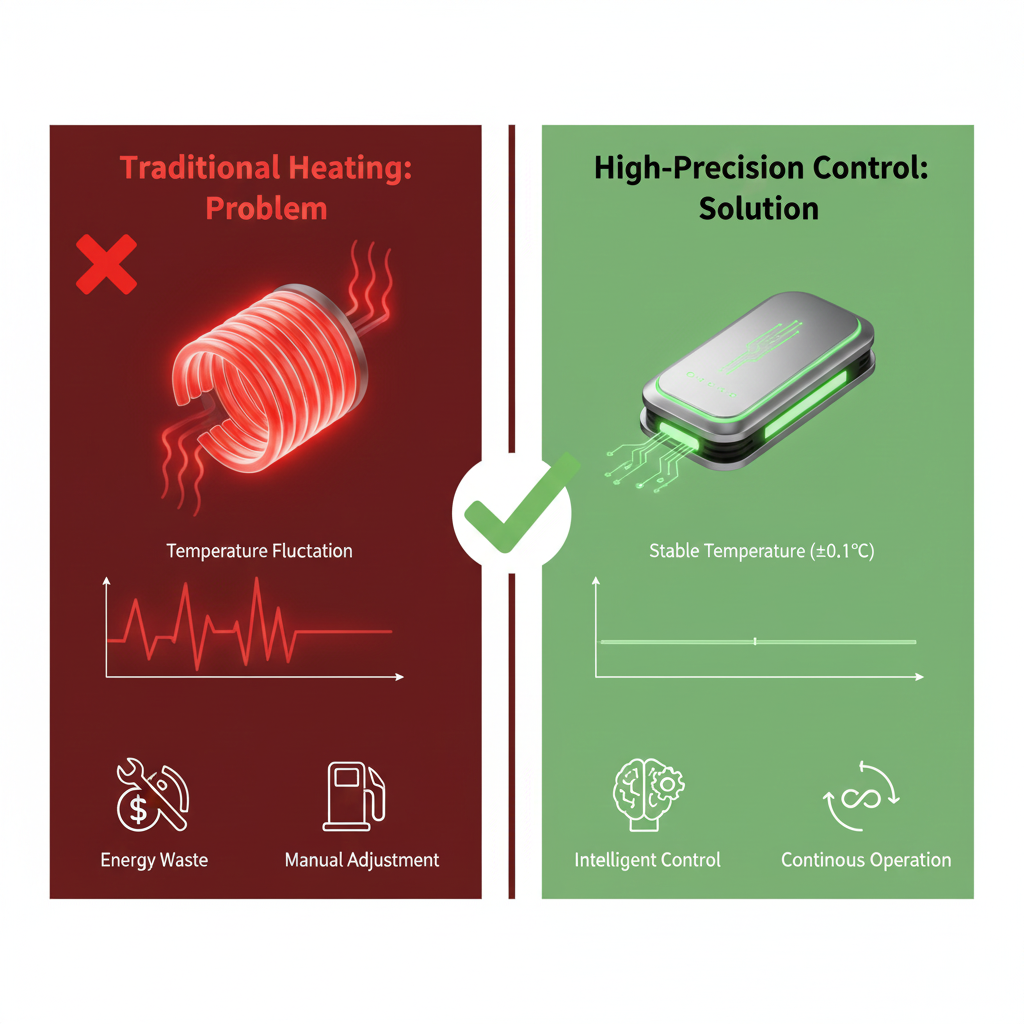

Industry Pain Points Addressed

1. Temperature Fluctuations Causing Process Instability

Traditional heating Solutions often suffer from overshoot, lag, and oscillation, especially during startup or load changes. These fluctuations result in process drift, inconsistent outputs, and increased scrap rates.

2. Inability to Meet Tight Tolerance Requirements

Conventional heaters lack the resolution and responsiveness required for modern industrial tolerances. High precision temperature control systems maintain narrow temperature bands, enabling compliance with strict quality standards.

3. High Energy Consumption and Inefficient Heating

Fixed-output or on/off heating methods waste energy and cause uneven heating. Precision systems modulate output in real time, reducing power consumption while improving thermal stability.

4. Equipment Wear and Reduced Lifespan

Repeated thermal cycling accelerates component fatigue. Stable and uniform temperature control significantly reduces thermal stress and maintenance frequency.

5. Limited Adaptability to Changing Process Conditions

Modern equipment operates under variable loads and environments. Intelligent temperature control systems adapt automatically, ensuring uninterrupted production.

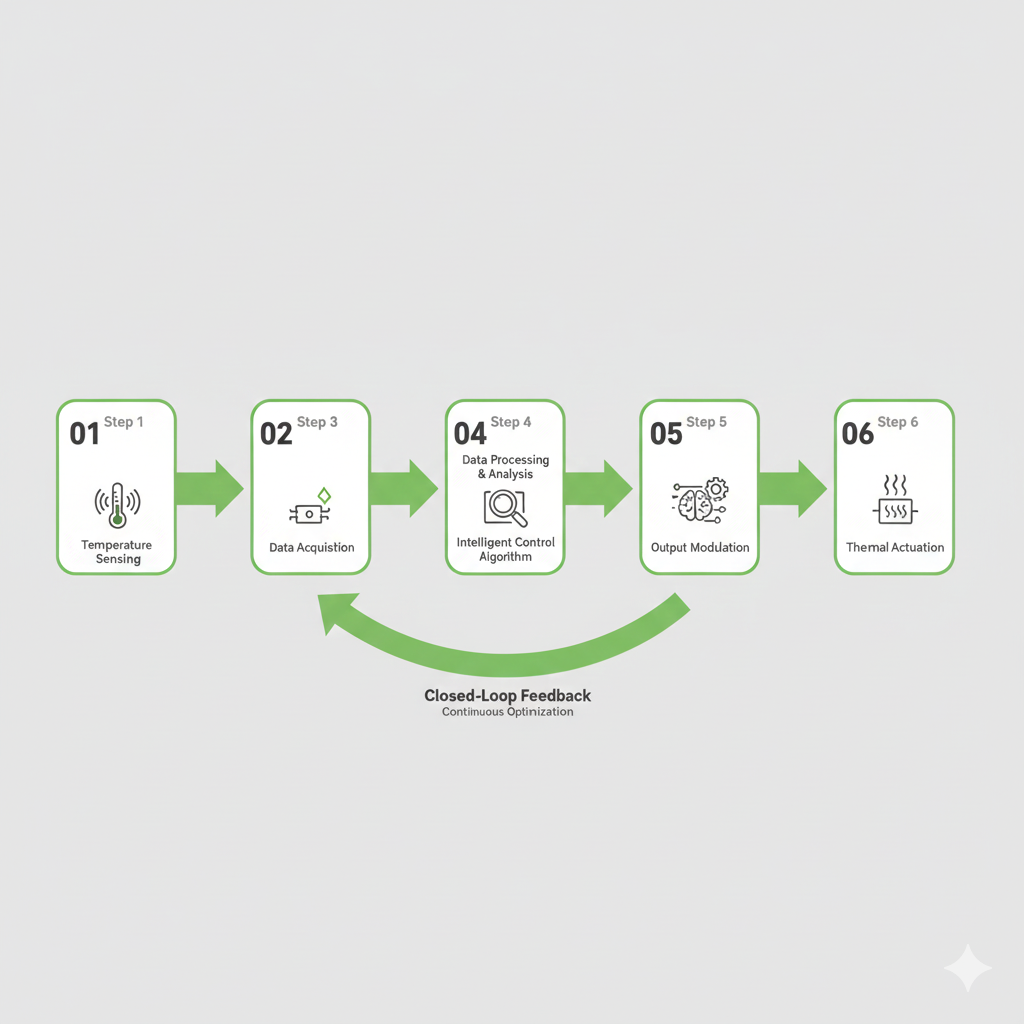

Working Principle (Step-by-Step)

Step 1: High-Resolution Temperature Sensing

Precision sensors continuously capture real-time temperature data with high resolution at critical control points.

Step 2: Real-Time Data Processing

Collected data is analyzed by the control unit to identify trends, rate changes, and potential disturbances.

Step 3: Intelligent Control Algorithm

Advanced PID or adaptive algorithms calculate optimal thermal output, considering system inertia and future load changes.

Step 4: Precise Output Modulation

The system adjusts heating output smoothly and continuously, avoiding overshoot and oscillation.

Step 5: Continuous Feedback Optimization

A closed-loop process enables ongoing refinement, improving stability, response speed, and energy efficiency.

![]()

Case Study

A semiconductor manufacturing facility experienced yield losses due to microscopic temperature variations in process chambers.

- Temperature stability improved: ±1.5°C → ±0.1°C

- Yield increased: Over 12%

- Energy consumption reduced: ~25%

- Maintenance events: Significantly reduced

The system enabled continuous operation without manual recalibration.

Comparison with Traditional Heating Methods

| Aspect | Traditional Heating | High Precision System |

|---|---|---|

| Temperature Accuracy | ±1–3°C | ±0.1–0.3°C |

| Energy Efficiency | Low | High |

| Control Method | On/Off | Adaptive Control |

| Maintenance | Frequent | Low |

FAQ

Q1: What industries benefit most?

Semiconductors, lasers, batteries, pharmaceuticals, and laboratories.

Q2: How precise is the control?

Typically within ±0.1°C.

Q3: Can it retrofit existing equipment?

Yes, modular integration is supported.

Q4: Does it save energy?

Yes, through optimized modulation.

Q5: Is maintenance reduced?

Significantly.

Q6: Can it handle variable loads?

Yes, adaptive algorithms respond in real time.

Q7: Is manual operation required?

No, autonomous operation after setup.

Q8: ROI timeframe?

Typically 12–24 months.

Authoritative Conclusion

Advanced high precision temperature control systems are no longer optional in modern industrial equipment. They enable accuracy, efficiency, and long-term reliability by eliminating temperature instability, reducing energy waste, and protecting critical assets.

For industries pursuing higher yields, lower operating costs, and future-ready manufacturing, precision temperature control is a strategic investment.