energy efficient industrial heating solution for stable industrial processes" width="1024" height="1024" />

energy efficient industrial heating solution for stable industrial processes" width="1024" height="1024" />

Definition

Replacing an electric heater with a heat pump refers to upgrading a conventional resistive heating system—where electricity is directly converted into heat—to a heat pump–based solution that transfers thermal energy from ambient or waste sources into the target heating application.

Unlike electric heaters with a fixed conversion efficiency (COP ≈ 1), heat pumps operate on thermodynamic cycles that enable them to deliver multiple units of usable heat per unit of electrical input. This results in significantly higher energy efficiency, lower operating costs, and improved temperature stability.

Industry Pain Points Solved

⚡ High Energy Consumption

Electric heaters consume one unit of electricity for one unit of heat, leading to high energy costs in continuous or industrial-scale operation. Heat pumps typically achieve COP values between 2 and 5, reducing electricity consumption by 40–70%.

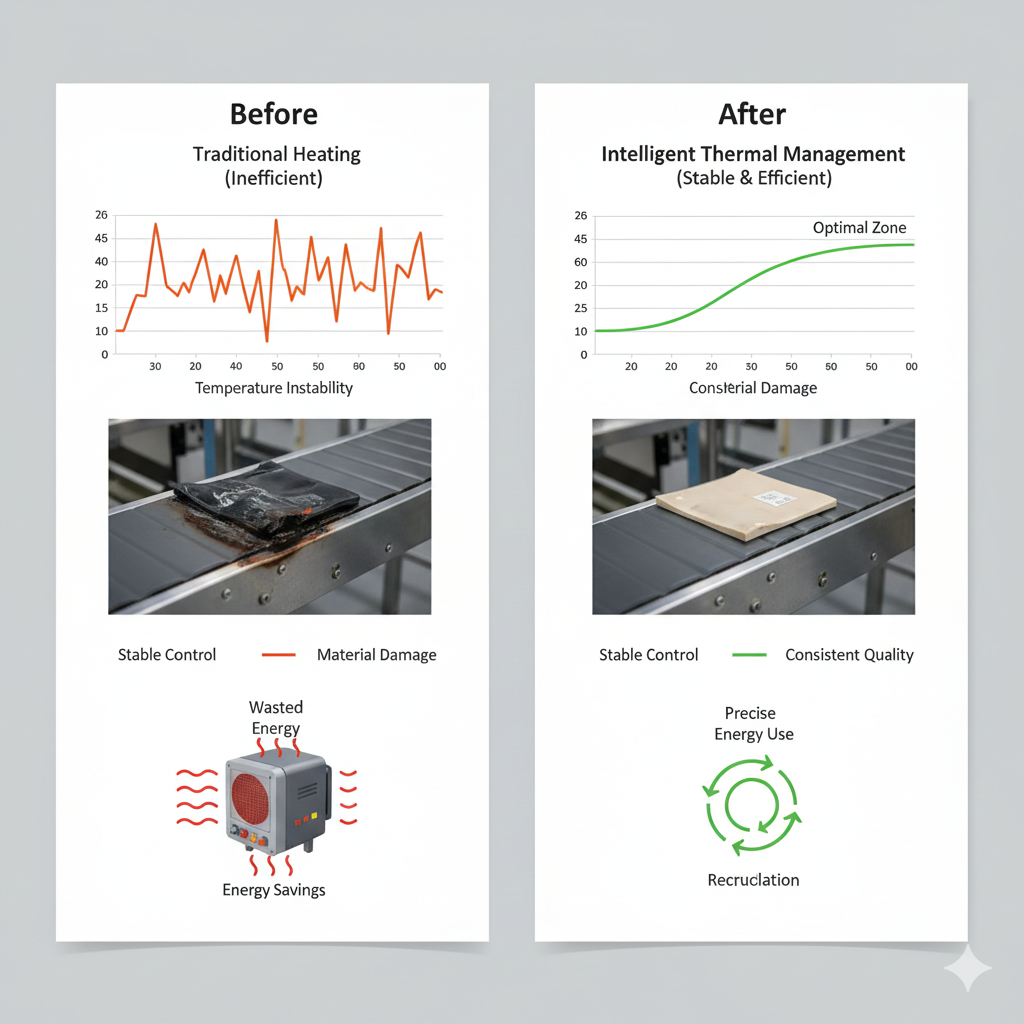

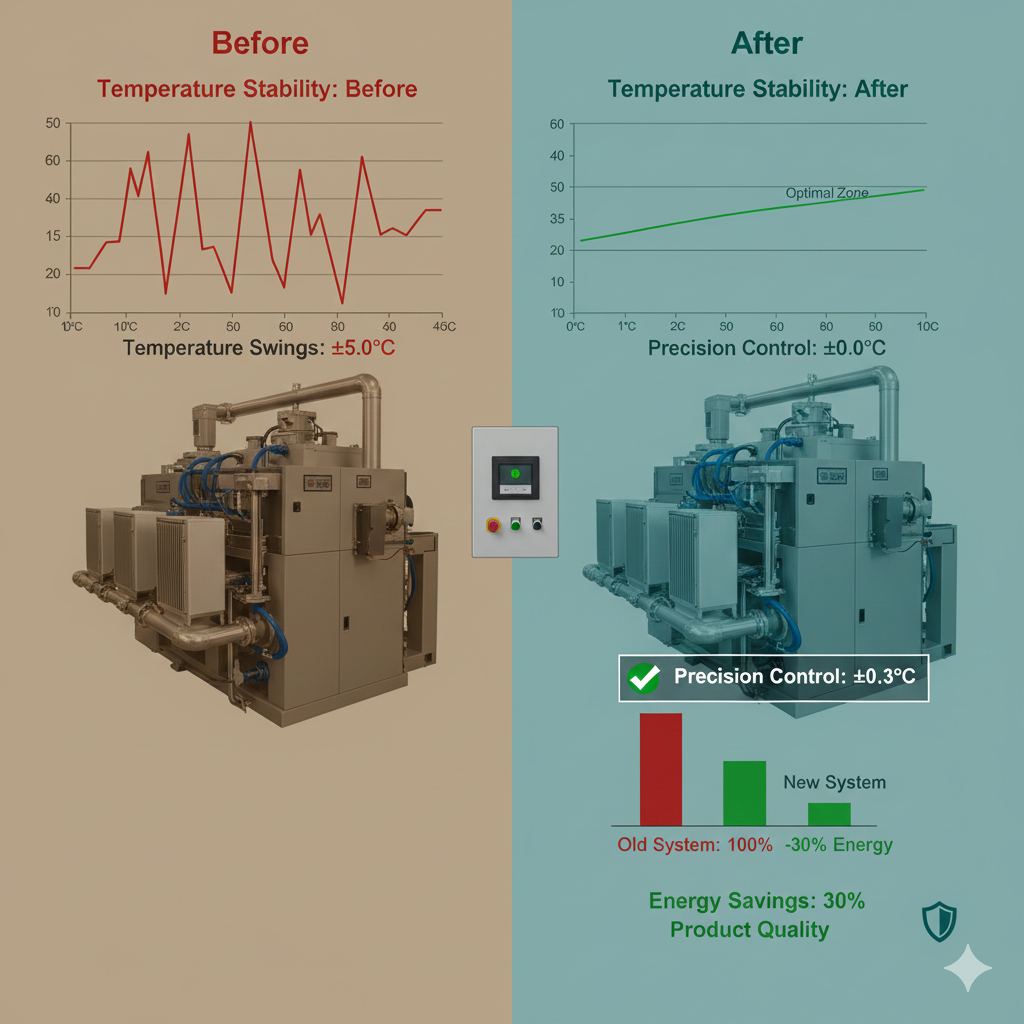

🎯 Poor Temperature Stability

Electric heaters rely on on/off control, which often causes temperature fluctuations and localized overheating. Heat pumps enable continuous modulation for smoother, more stable temperature control.

🔥 Safety and Component Stress

High surface temperatures of electric heaters increase risks of burns, material degradation, and fire hazards. Heat pump systems distribute heat more evenly and operate at lower surface temperatures.

🔧 Limited Scalability and Integration

Traditional heaters are difficult to scale or integrate with modern automation systems. Heat pumps support modular design and seamless PLC or BMS integration.

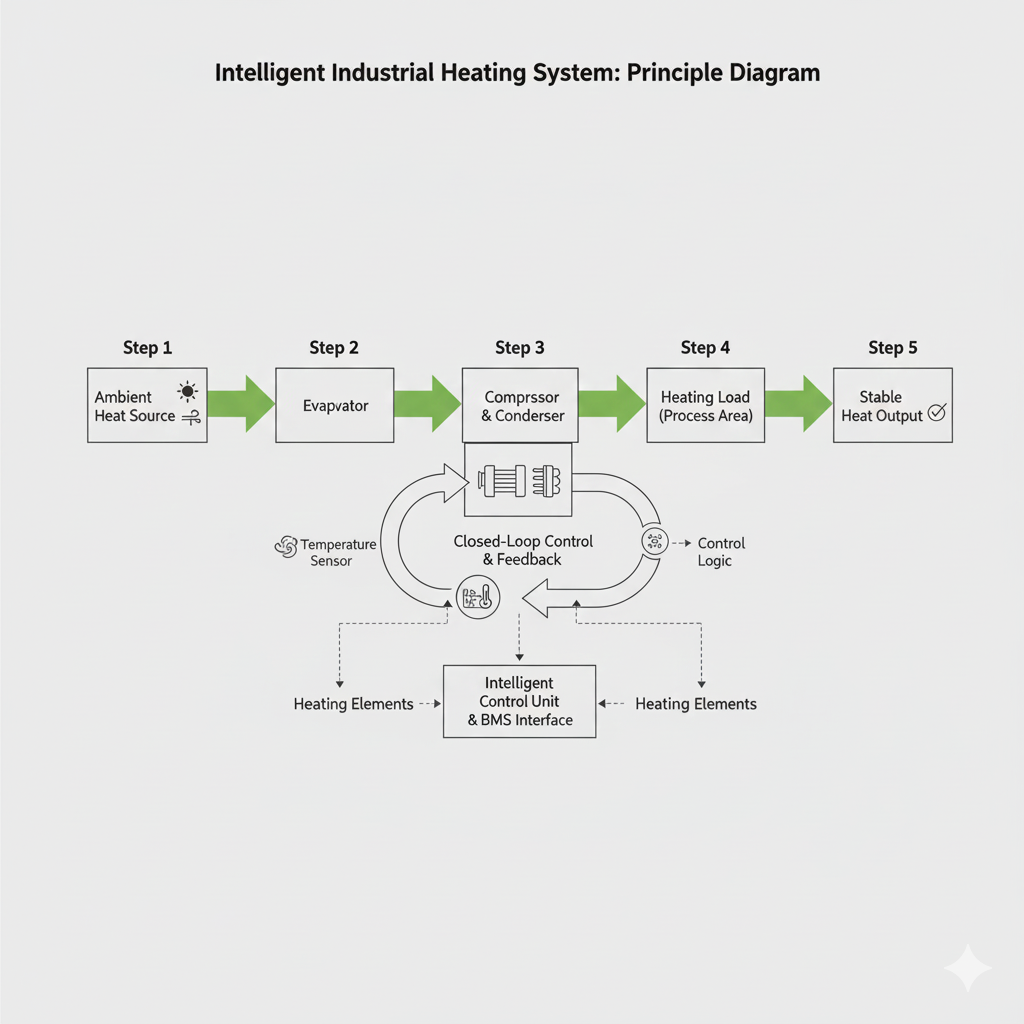

Working Principle (Step Structure)

Step 1: Electrical Power Input

Electrical energy drives the compressor and control system instead of directly generating heat.

Step 2: Heat Absorption

A refrigerant absorbs low-grade heat from ambient air, water, or industrial waste heat sources.

Step 3: Compression

The compressor raises the refrigerant’s pressure and temperature, converting low-grade heat into high-grade usable energy.

Step 4: Heat Release

Thermal energy is transferred to the target heating system through a condenser.

Step 5: Expansion and Cycle Continuation

The refrigerant pressure drops, and the cycle repeats for continuous high-efficiency heating.

Step 6: Intelligent Control

Sensors and control algorithms adjust output in real time to match heating demand precisely.

Case Study: Industrial Heating Upgrade

A manufacturing facility operating process tanks at 70–85 °C relied on electric immersion heaters, facing high electricity costs and frequent maintenance.

After replacing electric heaters with an industrial heat pump system, the facility achieved:

- ✔ Approximately 50% energy savings

- ✔ Temperature stability improved to ±0.3 °C

- ✔ Reduced maintenance and longer system lifespan

- ✔ Enhanced safety and sustainability compliance

Comparison with Traditional Electric Heating

| Aspect | Heat Pump | Electric Heater |

|---|---|---|

| Energy Efficiency | COP 2–5 | COP ≈ 1 |

| Operating Cost | Low | High |

| Temperature Stability | High | Limited |

| Safety | High | Moderate to Low |

| System Lifespan | Long | Shorter |

FAQ

Q1: Is replacing electric heaters with heat pumps feasible?

Yes, especially for applications below 90 °C.

Q2: Do heat pumps work in cold climates?

Modern systems are designed for low-temperature operation.

Q3: Is the initial investment higher?

Yes, but payback periods are typically short.

Q4: Is temperature control accurate?

Yes, advanced controls ensure high precision.

Q5: Are heat pumps safer?

They operate at lower surface temperatures.

Q6: What about maintenance?

Maintenance requirements are lower than electric heaters.

Q7: Can existing systems be retrofitted?

Yes, with minimal disruption.

Q8: Are heat pumps environmentally friendly?

They significantly reduce energy consumption and emissions.

Conclusion

Replacing electric heaters with heat pumps is a strategic upgrade that delivers higher energy efficiency, improved temperature control, enhanced safety, and long-term cost savings.

For industrial and laboratory heating systems facing rising energy prices and sustainability demands, heat pumps provide a future-ready solution that supports stable operation and reduced environmental impact.