battery thermal management heating system for industrial batteries" width="1024" height="1024" />

battery thermal management heating system for industrial batteries" width="1024" height="1024" />

Energy-efficient battery thermal management heating technology

refers to an integrated heating and control solution designed to actively regulate battery temperature

within an optimal operating range, particularly under low-temperature or variable environmental conditions.

Unlike passive insulation or conventional resistive heating, this technology focuses on

precise, intelligent, and energy-conscious thermal regulation

to ensure industrial battery systems operate safely, reliably, and efficiently throughout their lifecycle.

In industrial battery systems—such as energy storage systems (ESS), backup power units, off-grid installations,

and heavy-duty electric equipment—temperature stability directly impacts performance, safety, efficiency,

and longevity.

Key Industry Pain Points Addressed

- Severe performance degradation at low temperatures:

Reduced capacity, unstable voltage, and lower power output under cold conditions. - Cold start failures and system downtime:

Batteries may fail to initialize properly, compromising industrial reliability. - Accelerated aging and safety risks:

Low-temperature operation increases internal resistance and degradation risks. - High energy consumption from traditional heating:

Resistive heaters consume excessive energy with poor control. - Limited system integration:

Conventional Solutions lack intelligent coordination with BMS or controllers.

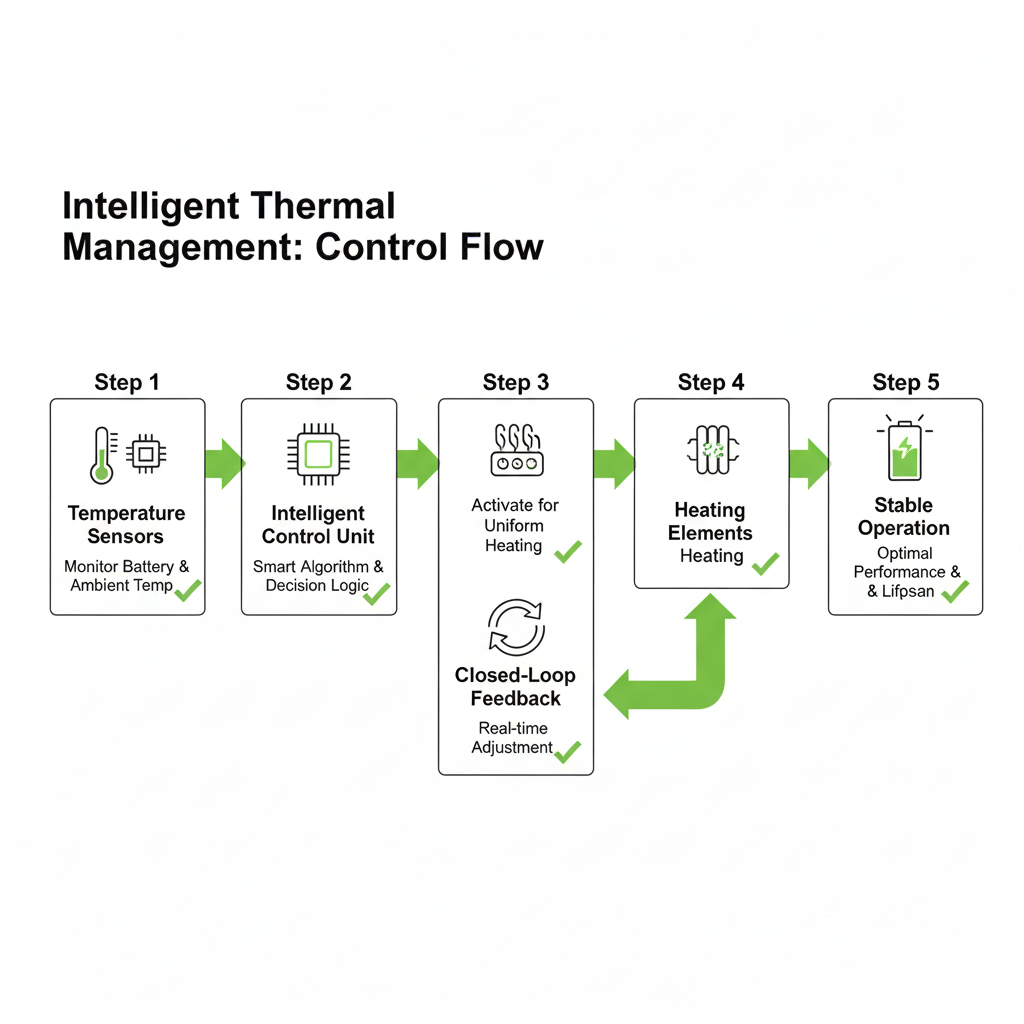

Working Principle (Step-by-Step)

Step 1 – Real-Time Temperature Monitoring

High-accuracy sensors continuously monitor battery cell and ambient temperatures.

Step 2 – Intelligent Control Logic

The control unit evaluates data against predefined thresholds and calculates heating demand.

Step 3 – Targeted and Uniform Heating

Heat is delivered directly and evenly to battery modules, avoiding thermal hotspots.

Step 4 – Closed-Loop Feedback Regulation

Continuous feedback dynamically adjusts heating power to maintain optimal temperature.

Step 5 – Standby and Maintenance Heating

Once optimal temperature is reached, low-power compensation maintains stability efficiently.

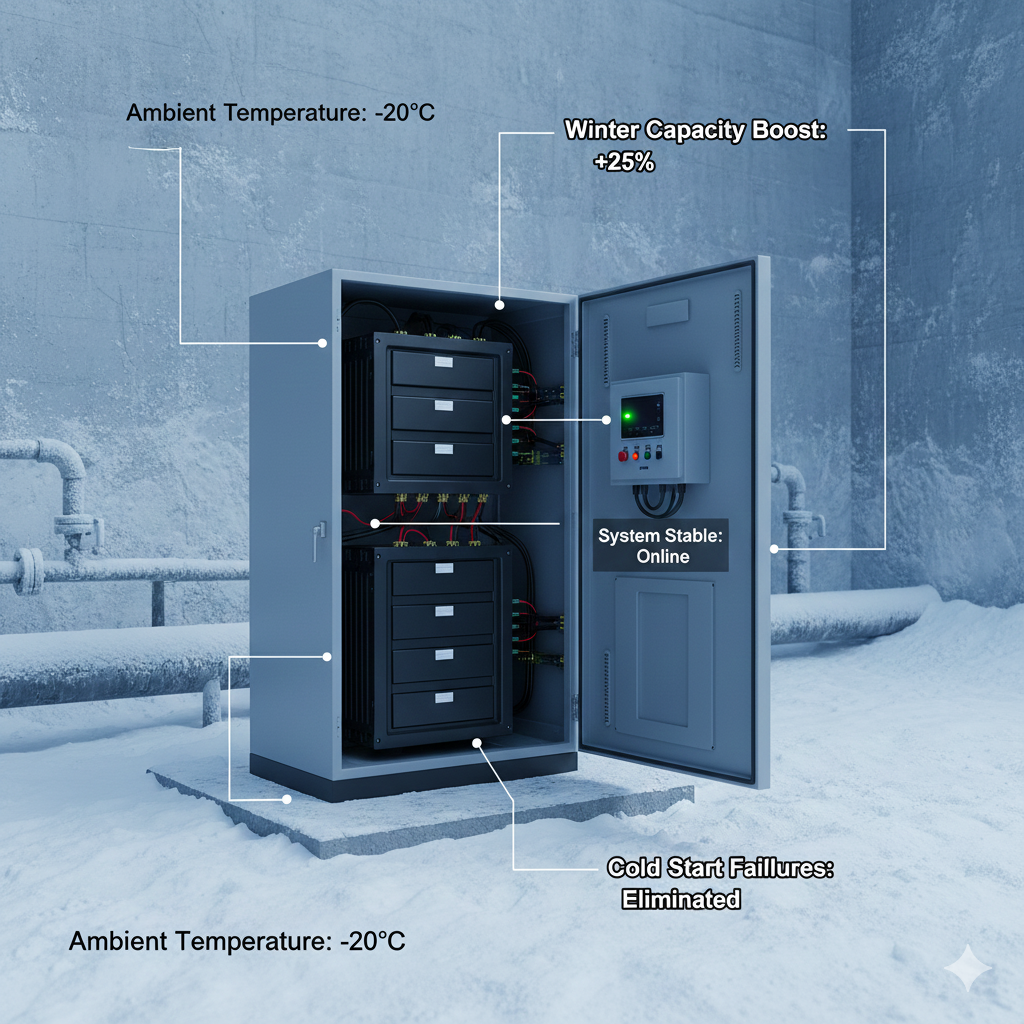

Case Study: Industrial Energy Storage System in Cold Climate

An industrial energy storage facility located in a northern region experienced recurring operational issues

during winter months, with ambient temperatures dropping below -20°C.

After integrating an energy-efficient battery thermal management heating system directly with the BMS,

batteries were preheated and maintained within an optimal operating range.

- Winter usable capacity increased by approximately 20–30%

- Cold start failures were virtually eliminated

- Heating energy consumption reduced by over 30%

- Battery lifespan significantly extended

Comparison with Traditional Heating Methods

| Dimension | Battery Thermal Management Heating | Resistive Heating | Ambient Heating |

|---|---|---|---|

| energy efficiency | High, targeted control | Low | Very low |

| Temperature Accuracy | Precise, closed-loop | Limited | Poor |

| Heating Uniformity | Excellent | Uneven | Uncontrolled |

| Safety | High | Overheating risk | Unpredictable |

| System Integration | Seamless with BMS | Limited | None |

Frequently Asked Questions (FAQ)

- Is thermal management heating necessary for all industrial battery systems?

- Does it significantly increase energy consumption?

- Can it be integrated with existing systems?

- Which battery chemistries are supported?

- How does it improve battery lifespan?

- Is long-term continuous operation safe?

- What maintenance is required?

- Can it operate in extremely low temperatures?

Authoritative Conclusion

Energy-efficient battery thermal management heating technology is a critical foundation for modern

industrial battery systems. By addressing low-temperature performance degradation, safety risks,

and excessive energy consumption, it enables stable, reliable, and long-term battery operation.

For industrial applications where reliability and efficiency are essential, this technology is

not optional—it is a system-level requirement.