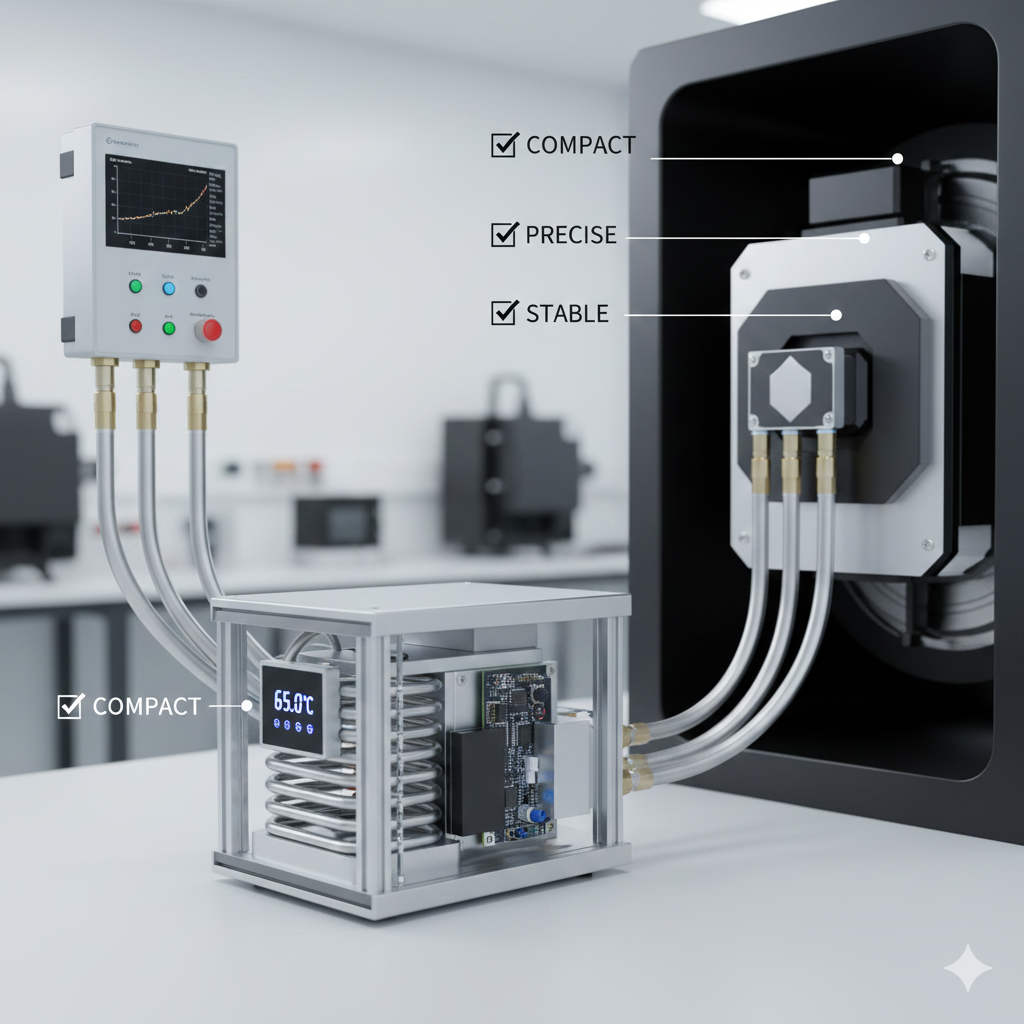

A laser system heating unit is a dedicated thermal management subsystem designed to deliver

stable, accurate, and repeatable heat to critical components within a laser system.

Its primary function is to maintain laser-related elements—such as laser sources, optical assemblies,

resonators, and fluid circuits—within a tightly controlled temperature window,

ensuring consistent laser output, optical alignment stability, and long-term system reliability.

Unlike conventional heaters that rely on simple resistive heating,

a modern laser system heating unit is engineered as a

precision temperature control device,

integrating controlled heat generation, uniform heat transfer, and closed-loop regulation.

In high-performance laser systems, even minor temperature fluctuations can directly affect

wavelength stability, beam quality, and operational safety.

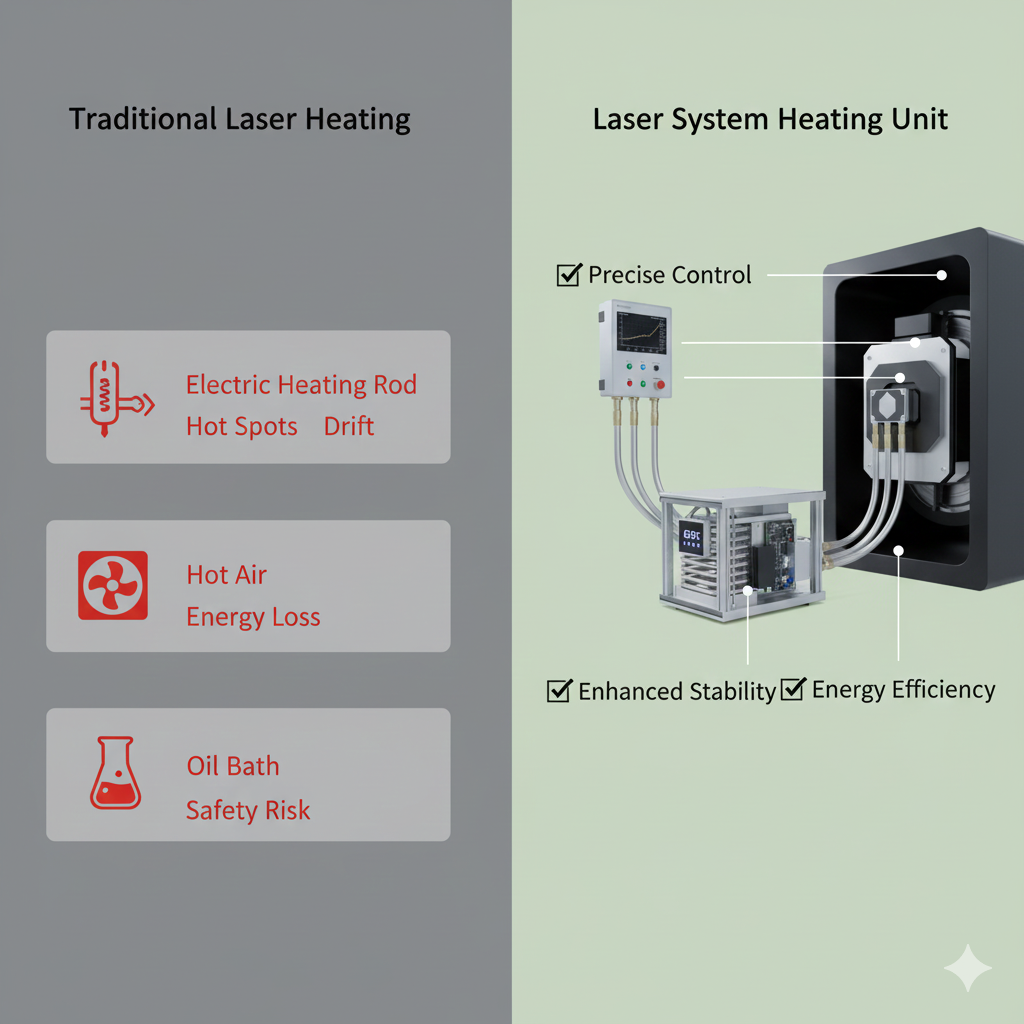

Industry Pain Points Addressed

Temperature Sensitivity of Laser Components

Laser systems are highly sensitive to temperature variation.

Semiconductor laser diodes, solid-state laser crystals, and optical coatings

experience performance drift under unstable thermal conditions.

Traditional heating Solutions struggle to maintain the tight tolerance required,

leading to wavelength shift, output instability, and degraded beam quality.

Inconsistent Thermal Distribution

Conventional heaters often generate localized hot spots.

These uneven temperature profiles introduce mechanical stress,

optical misalignment, and refractive index variation,

ultimately shortening component lifespan and increasing failure risk.

Slow Response and Poor Control Accuracy

Many heating systems suffer from high thermal inertia,

resulting in slow startup and delayed response to load changes.

This makes it difficult to stabilize laser systems quickly

or maintain precise control during dynamic operation.

Energy Inefficiency and High Operating Cost

Resistive heating converts electricity directly into heat with minimal optimization,

leading to excessive energy consumption in continuous-duty laser systems.

Safety and Reliability Concerns

Exposed high-temperature elements increase the risk of burns,

component damage, and unintended thermal interaction,

posing challenges in controlled laboratory and industrial environments.

Working Principle of a Laser System Heating Unit

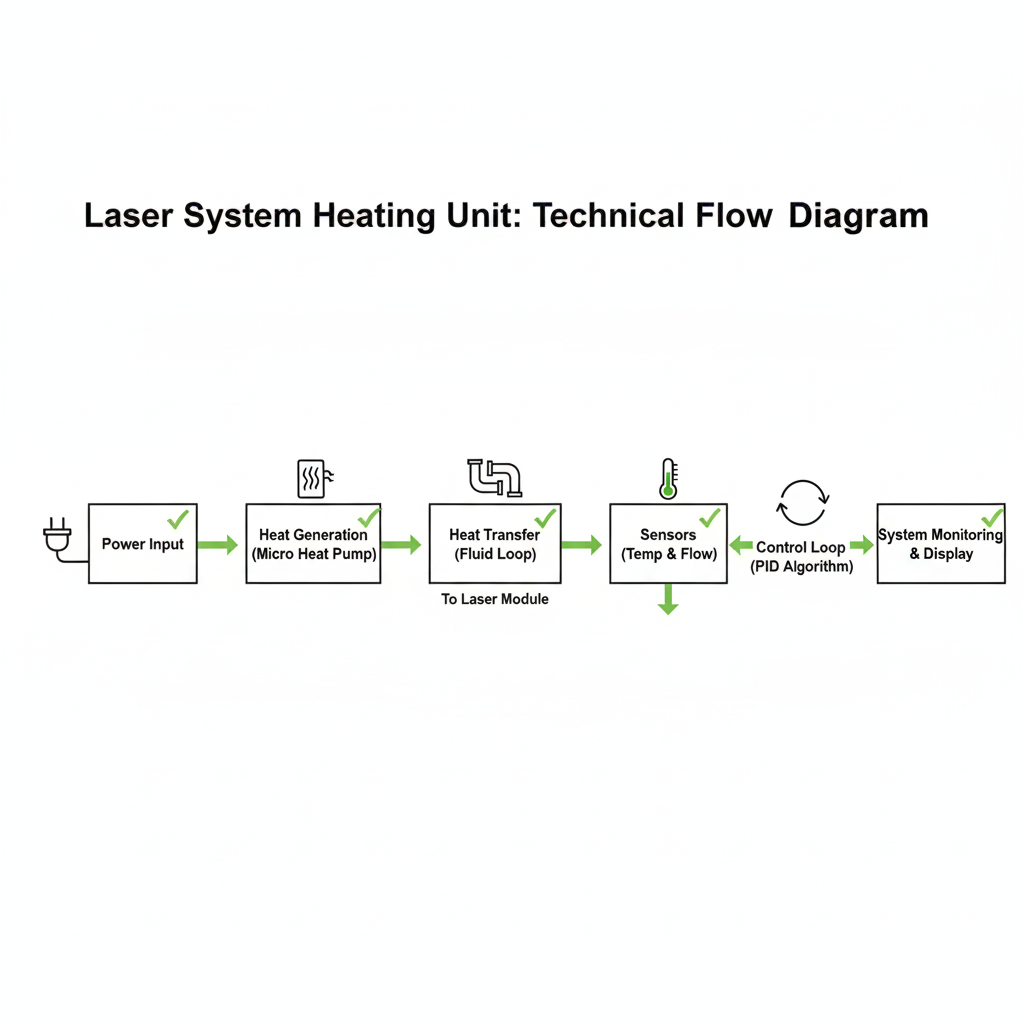

🔹 Step 1: Power Input and Control Activation

The heating unit receives electrical power and activates its control system.

Temperature sensors distributed across the laser system continuously monitor

critical points and provide real-time feedback.

🔹 Step 2: Controlled Heat Generation

Heat is generated in a regulated manner rather than uncontrolled resistive output.

Heating power is dynamically modulated to precisely match system demand.

🔹 Step 3: Efficient Heat Transfer

Generated heat is delivered through optimized conduction paths,

fluid loops, or heat exchangers to ensure smooth and uniform thermal distribution.

🔹 Step 4: Closed-Loop Temperature Regulation

Sensor feedback enables advanced control algorithms to continuously adjust heating output,

maintaining the target temperature within a narrow tolerance band.

🔹 Step 5: Thermal Stability Maintenance

Once equilibrium is reached, the system fine-tunes output to counteract

ambient fluctuations and load variation without overshoot or oscillation.

🔹 Step 6: System Protection and Monitoring

Integrated safety functions detect abnormal conditions and initiate

protective actions to safeguard the laser system.

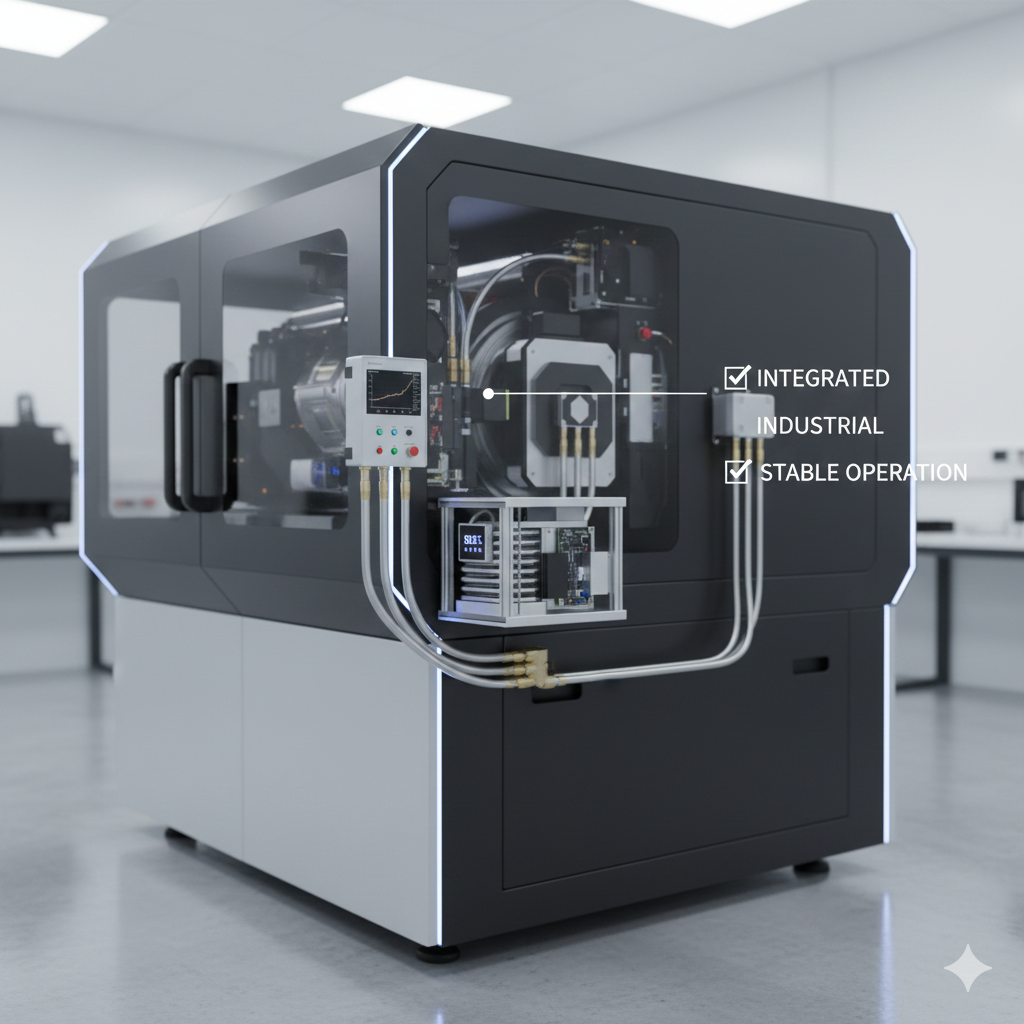

Application Case Study

Background

An industrial laser manufacturer producing high-precision laser cutting systems

experienced performance instability during long-duration operation.

The laser source and optics required stable operation within 65–75°C,

yet existing heating solutions caused temperature fluctuations exceeding ±1.5°C.

Implemented Solution

A dedicated laser system heating unit was integrated into the platform,

directly interfacing with the system’s thermal management loop

to provide controlled heat input and precise regulation.

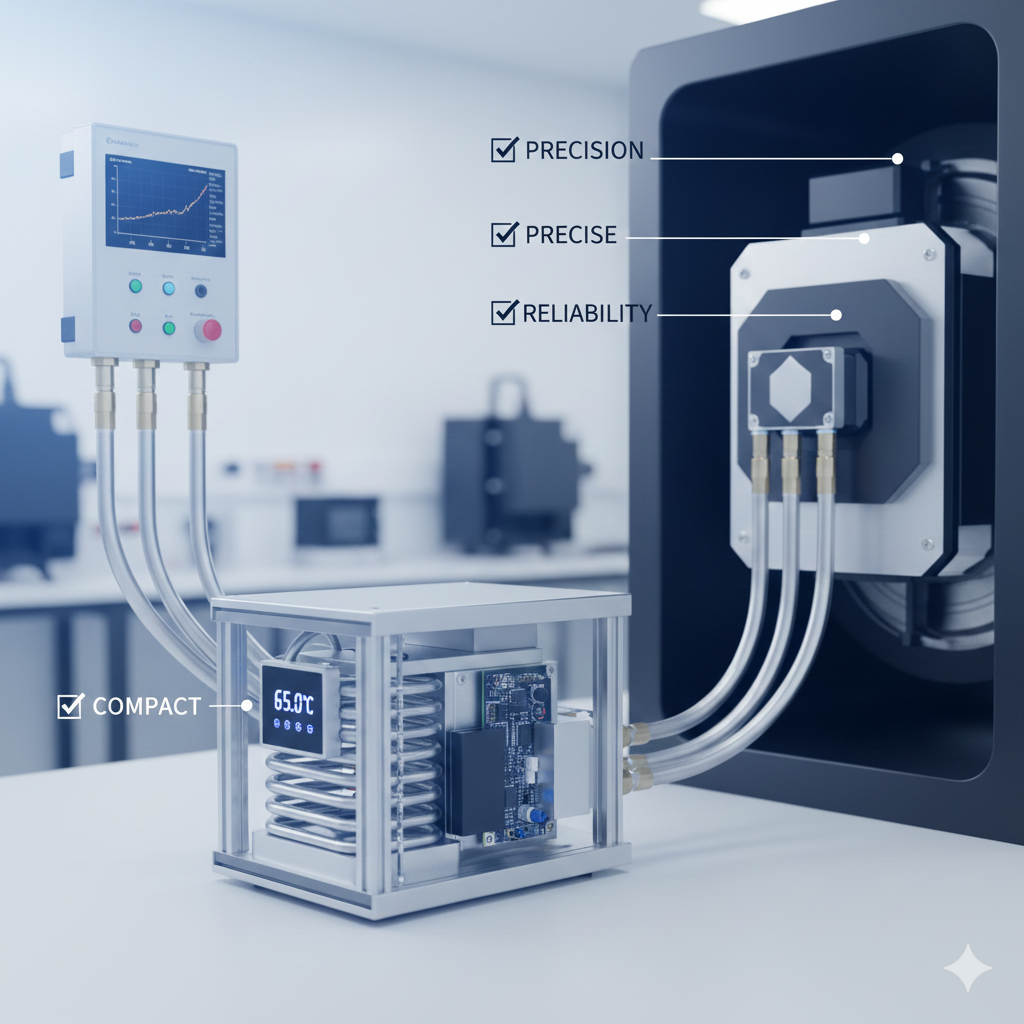

Operational Process

The heating unit rapidly elevated components to target temperature during startup

and dynamically adjusted output during continuous operation

to compensate for ambient and load variations.

Results

- Temperature stability improved to ±0.2°C

- Beam quality consistency significantly increased

- Thermal management energy consumption reduced by ~30%

- System uptime improved due to reduced thermal stress

Comparison with Traditional Heating Methods

| Aspect | Laser System Heating Unit | Resistive Heater | Hot Air Heating | Oil Bath |

|---|---|---|---|---|

| Temperature Stability | ±0.1–0.3°C | Limited | Poor | Moderate |

| Response Speed | Fast | Slow | Slow | Very Slow |

| energy efficiency | Optimized | Low | Low | Low |

| Safety | High | Low | Medium | Low |

Frequently Asked Questions

FAQ 1: Why is temperature control critical in laser systems?

Temperature stability directly impacts wavelength accuracy, beam quality, and output consistency.

FAQ 2: Can this unit replace traditional heaters?

Yes, it is specifically designed to outperform conventional solutions.

FAQ 3: What temperature range is supported?

Units typically support mid-range laser operating temperatures with customization available.

FAQ 4: How accurate is temperature control?

High-quality systems achieve ±0.1–0.3°C stability.

FAQ 5: Is continuous operation supported?

Yes, systems are engineered for long-term industrial use.

FAQ 6: Does it increase system complexity?

No, modular design allows straightforward integration.

FAQ 7: How does it affect energy consumption?

Optimized thermal control reduces overall energy usage.

FAQ 8: Is maintenance frequent?

Maintenance requirements are minimal.

Conclusion

A laser system heating unit is a critical enabler of

precise, stable, and energy-efficient temperature control

in modern laser systems.

By eliminating uneven heating, improving response speed,

and maintaining tight thermal tolerances,

it delivers superior performance, safety, and reliability.

For industrial, scientific, and advanced manufacturing laser applications,

integrating a dedicated laser system heating unit represents

a strategic investment in long-term system stability and performance excellence.