An industrial micro heat pump–based lab water heating system

is a compact, electrically driven thermal solution designed to deliver precise, stable, and energy-efficient hot water for laboratory applications.

By transferring low-grade heat from ambient air, cooling water, or system waste heat, it enables controlled laboratory water heating

with significantly lower energy consumption than conventional electric heating technologies.

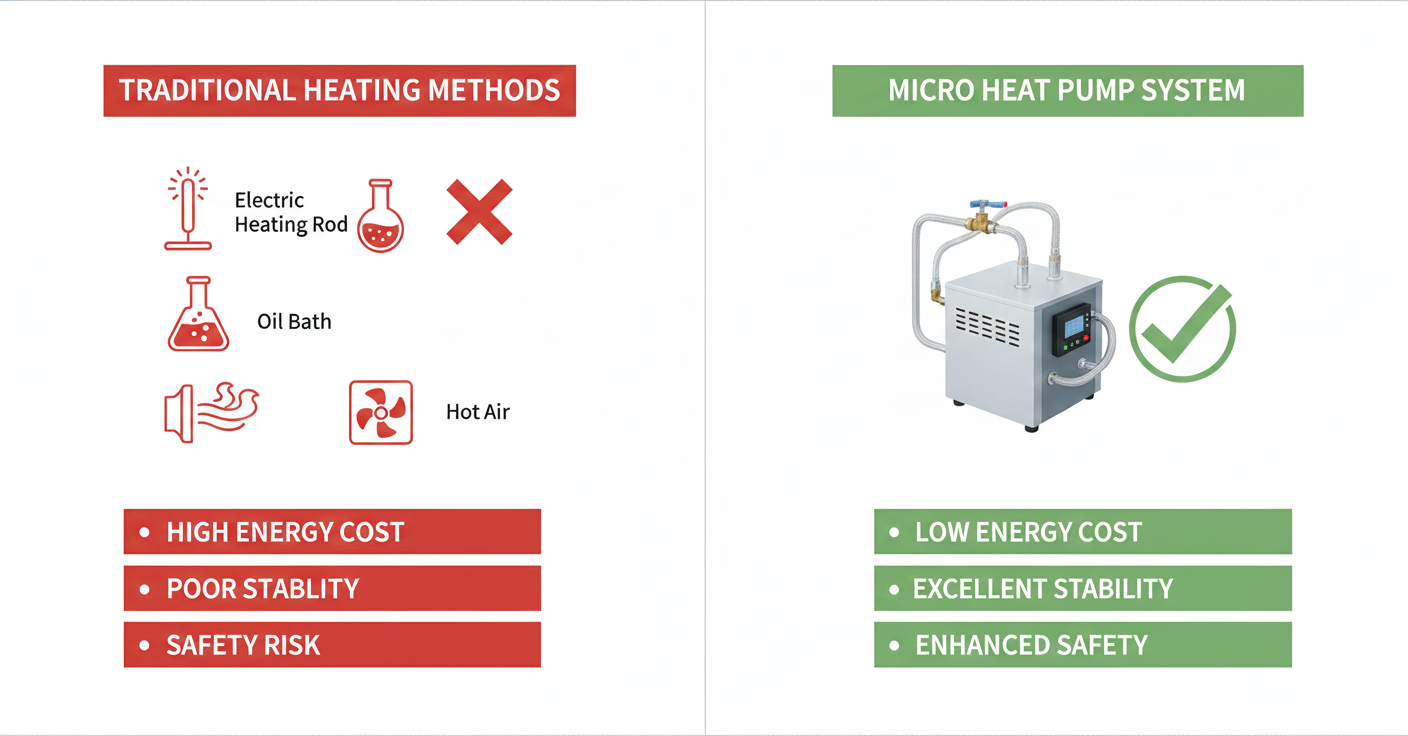

Industry Pain Points Solved

High energy consumption and operating cost

Conventional electric immersion heaters and resistance-based systems typically operate at a coefficient of performance (COP) close to 1.

An industrial micro heat pump transfers heat rather than generating it, achieving COP values typically between 2 and 4,

significantly reducing electricity consumption and long-term operating costs.

Limited temperature stability and control accuracy

Many laboratory processes require tight temperature tolerances.

Industrial micro heat pumps integrated with closed-loop control systems enable precise modulation of heat output,

maintaining temperature stability within ±0.1–0.3 °C.

Large footprint and poor system integration

Traditional oil baths and hot air heaters require bulky infrastructure.

Industrial micro heat pumps feature compact, modular designs that integrate directly into laboratory water heating modules.

Slow thermal response and uneven heating

High thermal inertia systems respond slowly.

Optimized heat exchangers and controlled circulation allow micro heat pumps to deliver fast response and uniform heat distribution.

Safety and environmental constraints

Oil leakage, exposed heaters, and high surface temperatures increase risk.

Industrial micro heat pumps operate without open flames or consumable heating media,

improving laboratory safety and cleanliness.

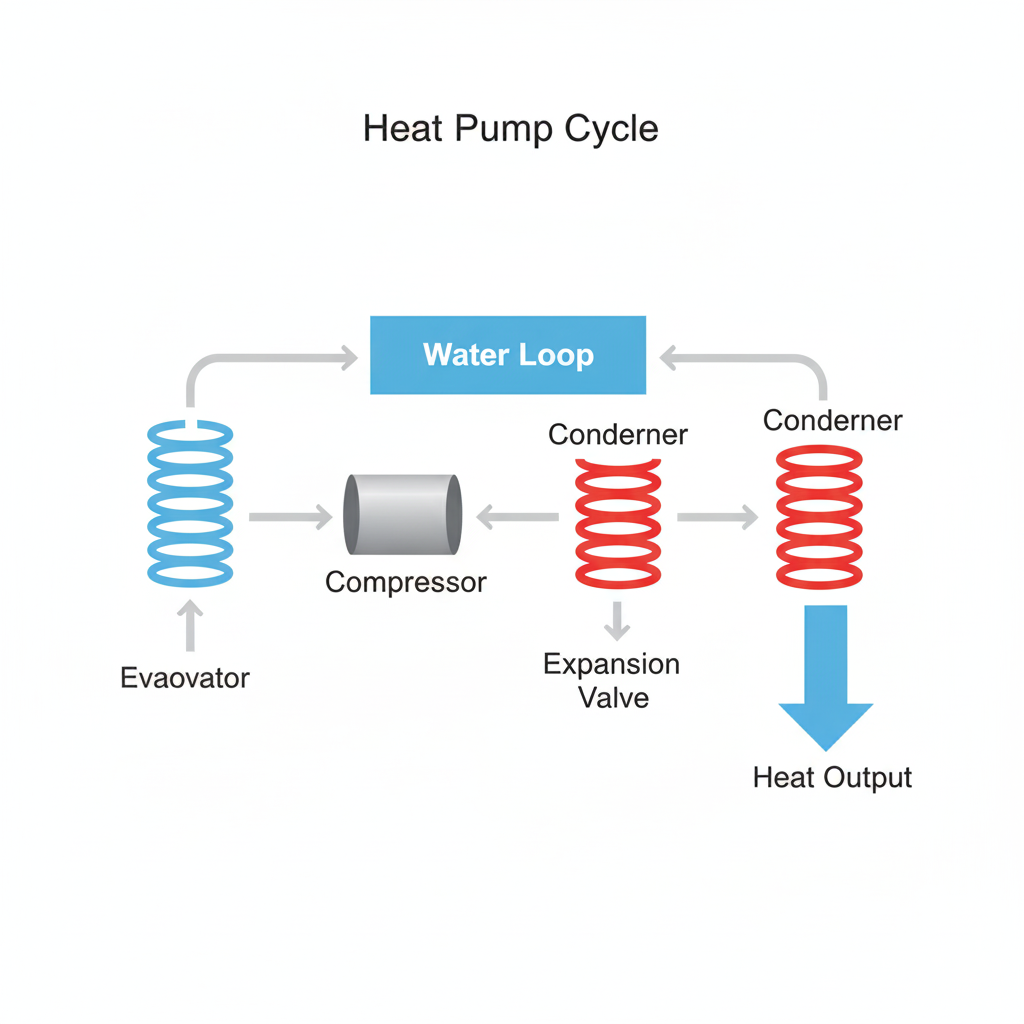

Working Principle

- Step 1: An electric motor drives a compact compressor, establishing closed-loop refrigerant circulation.

- Step 2: Low-pressure refrigerant absorbs heat from ambient air, cooling water, or waste heat sources.

- Step 3: The vaporized refrigerant is compressed, increasing pressure and temperature.

- Step 4: Heat is transferred to the laboratory water loop through a condenser heat exchanger.

- Step 5: Refrigerant passes through an expansion device, reducing pressure before returning to the evaporator.

- Step 6: Sensors and control algorithms regulate compressor speed for precise temperature control.

- Step 7: Pumps, buffer tanks, and safety interlocks ensure continuous laboratory operation.

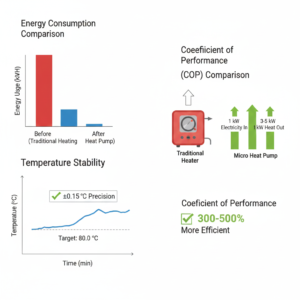

Application Case Study

A materials research laboratory required a stable 80 °C circulating water supply for polymer aging and durability testing.

Continuous operation placed high demands on temperature stability and energy efficiency.

Original configuration:

Electric immersion heaters delivering 10 kW thermal output with COP ≈ 1.

Annual energy consumption exceeded 10,000 kWh.

Upgraded solution:

An industrial micro heat pump–based system delivering the same 10 kW output at a COP of approximately 2.8.

- Electrical input reduced to approximately 3.6 kW

- Annual energy consumption reduced by approximately 64%

- Temperature stability improved to ±0.15 °C

- Compact integration into existing laboratory equipment

- Improved operational safety and reduced maintenance demand

Comparison with Traditional Heating Methods

| Parameter | Industrial Micro Heat Pump | Electric Heater | Hot Air Heating | Oil Bath |

|---|---|---|---|---|

| Energy Efficiency (COP) | 2.0–4.0 | ≈1.0 | ≈1.0 | ≈1.0 |

| Operating Cost | Low | High | High | High |

| Temperature Stability | High | Medium | Low | Medium |

| Safety | High | Medium | Medium | Low |

heat pump vs electric heater" src="https://zhenmingzhu.com/wp-content/uploads/2025/12/comparison-of-lab-heating-methods-micro-heat-pump-vs-electric-heater.png" alt="" width="1024" height="1024" />

Frequently Asked Questions

FAQ 1: Can an industrial micro heat pump reliably maintain 80 °C laboratory water temperature?

Yes. Stable operation in the 60–80 °C range is achievable.

FAQ 2: Is energy saving significant compared to electric heating systems?

Energy consumption can be reduced by 30–70%.

FAQ 3: Will compressor noise affect laboratory environments?

Modern micro compressors operate at low noise levels.

FAQ 4: What maintenance does the system require?

Routine inspection and scheduled compressor servicing.

FAQ 5: Can the system be retrofitted into existing laboratory equipment?

Yes. Compact modular design supports retrofitting.

FAQ 6: Are refrigerants safe for laboratory environments?

Compliant refrigerants with leak protection are used.

FAQ 7: Can the system provide cooling as well as heating?

Many systems support bidirectional operation.

FAQ 8: How is system capacity selected?

Capacity depends on thermal load, target temperature, and duty cycle.

Conclusion

Industrial micro heat pump–based lab water heating systems deliver high efficiency, precise temperature control,

and enhanced safety by transferring heat instead of generating it directly.

Their compact design, low noise, and long service life make them ideal for continuous laboratory operation,

offering clear technical and economic advantages over traditional heating technologies.