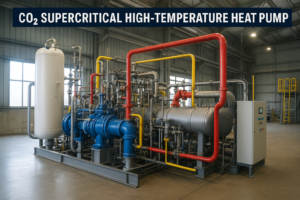

The CO₂ Supercritical High-Temperature Heat Pump is an advanced energy-efficient technology designed to generate high-temperature heat for industrial and commercial applications. Leveraging the supercritical properties of CO₂, this heat pump achieves high energy efficiency and significantly reduces carbon emissions compared to traditional fossil fuel-based boilers.

History and Development

The concept of CO₂ supercritical high-temperature heat pumps originated in the early 2000s as industries sought alternatives to conventional fossil fuel boilers. Early research focused on transcritical cycles of CO₂, optimizing compressors and heat exchangers to achieve high-temperature outputs. Over the last decade, advances in materials, compressors, and system integration have enabled industrial-scale deployment of these heat pumps in Europe, Japan, and China.

Working Principle

The CO₂ supercritical high-temperature heat pump operates based on the transcritical cycle of CO₂ as a refrigerant. Unlike traditional heat pumps that operate below the critical point of the working fluid, CO₂ surpasses the supercritical point, allowing for:

- Rapid heat transfer at high temperatures (up to 120–130°C)

- Compact system design

- High coefficient of performance (COP) in industrial settings

The system consists of a CO₂ compressor, gas cooler, expansion valve, and evaporator. Heat extracted from low-temperature sources such as waste heat, geothermal, or ambient air is elevated to high temperatures suitable for industrial processes.

Classification

CO₂ supercritical high-temperature heat pumps can be categorized by their heat source and application:

- Air-source CO₂ heat pumps: Extract heat from ambient air, suitable for moderate-temperature industrial processes.

- Water-source CO₂ heat pumps: Use industrial wastewater or geothermal water as the heat source, providing stable output.

- Hybrid systems: Combine multiple heat sources for continuous operation and efficiency.

Applications

These heat pumps are widely used in industries where high-temperature heat is required, including:

- Food and beverage processing (pasteurization, sterilization)

- Textile dyeing and finishing

- Paper and pulp production

- Chemical manufacturing

- District heating systems

Case Study

In a European beverage factory, a CO₂ supercritical high-temperature heat pump replaced a 5 MW gas boiler. The system provided process heat at 110°C using waste heat from refrigeration units. Annual energy savings exceeded 30%, and CO₂ emissions were reduced by approximately 2,500 tons per year, demonstrating both economic and environmental benefits.

Advantages Compared to Traditional Boilers

| Feature | CO₂ Supercritical High-Temperature Heat Pump | Coal/Gas Boiler |

|---|---|---|

| Energy Efficiency | High COP of 2.5–3.5 | Efficiency typically 70–85% |

| Carbon Emissions | Significantly reduced, especially when using renewable heat sources | High CO₂ emissions per MWh |

| Temperature Output | Up to 130°C | Up to 200°C, but less efficient |

| Operational Safety | No combustion, lower fire risk | Combustion-based, higher risk |

| Maintenance | Lower long-term maintenance | High maintenance due to burners, flues, and ash handling |

Future Development Trends

The future of CO₂ supercritical high-temperature heat pumps includes:

- Integration with renewable energy sources (solar thermal, geothermal)

- Large-scale industrial adoption for energy-intensive processes

- Enhanced system design for higher temperature and efficiency

- Policy-driven incentives to replace fossil fuel boilers in factories