The toothpaste production process involves multiple heat energy demand links, including raw material mixing, heating, disinfection, sterilization, equipment cleaning, etc. Traditional heating methods usually rely on energy-intensive methods such as coal-fired boilers and electric heating equipment. These methods not only have high energy consumption, but also impose a certain burden on the environment. As an energy-saving and environmentally friendly heat energy conversion device, high-temperature heat pumps have important application potential in toothpaste production.

High-temperature heat pumps can recycle waste heat generated during the production process (such as waste heat in wastewater), and raise low-temperature waste heat to the required high temperature for production use, greatly improving energy utilization efficiency and reducing corporate energy expenditure and carbon emissions.

Main heat energy demand in toothpaste production

- Mixing and heating

- Process: Mix and heat the raw materials of toothpaste such as water, surfactants, flavors, etc. to a suitable temperature to ensure full mixing and fluidity of the raw materials.

- Temperature requirement: 60~90°C.

- Heat source requirement: hot water or steam.

- Disinfection and sterilization

- Process: In order to ensure the hygiene and safety of toothpaste Products, the toothpaste mixture or packaging container needs to be disinfected during the production process.

- Temperature requirement: 85~100°C.

- Heat source requirement: high-temperature hot water or steam.

- Cleaning equipment

- Process: Clean production equipment, pipes and containers to ensure the hygiene of the production environment.

- Temperature requirement: 70~90°C.

- Heat source requirement: hot water.

- Process: During the production process, especially the heating link, waste heat (such as 60°C wastewater) is usually generated. This waste heat can be recovered and used for preheating or cleaning in other process links.

- Heat source requirement: low-temperature hot water.

Application scenarios of high-temperature heat pumps in toothpaste production

- Wastewater waste heat recovery

In toothpaste production, part of the heat comes from high-temperature wastewater, which is usually about 60°C. The traditional practice is to directly discharge the wastewater or treat it through a cooling tower, but this will cause energy waste. High-temperature heat pumps can recover the waste heat of these low-temperature wastewaters and heat them to 90°C or higher for use in the mixing, disinfection, cleaning and other process links in the production line.

- For example: Assuming that the wastewater temperature generated in toothpaste production is 60°C and the flow rate is 5 tons/hour (5000 kg/h), the heat required to heat these wastewaters to 90°C through a high-temperature heat pump can be calculated according to the formula :

The COP value of the high-temperature heat pump is assumed to be 4.5, and the required electrical energy is:

By recovering the waste heat of wastewater and using high-temperature heat pumps, companies can significantly reduce energy consumption.

- High-temperature heat pumps provide a stable heat source for heating and disinfection

In the heating and disinfection links of toothpaste production, boilers or electric heating equipment are traditionally used to provide heat energy. These equipment have problems such as low energy efficiency and environmental pollution. High-temperature heat pumps can provide a stable and efficient heat source for these links. Especially in the disinfection link, high-temperature heat pumps can recover waste heat or other heat sources and heat them to the required high temperature, reducing the demand for external energy.

- Example: Assuming that the disinfection process requires hot water at 90°C, if boilers or electric heating equipment are used directly, a lot of energy will be consumed. By using a high-temperature heat pump to recover the 60°C heat in the wastewater, the required heat can be achieved without consuming too much extra energy through the warming effect of the heat pump, significantly improving the energy efficiency of production.

- Heat source supply in the cleaning process

The production equipment and pipelines need to be cleaned frequently during the toothpaste production process. High-temperature heat pumps can provide stable hot water at 70~90°C for use in the cleaning process. This can not only improve cleaning efficiency and reduce manual cleaning time, but also reduce dependence on steam boilers or other traditional heat sources.

- Example: By using hot water provided by high-temperature heat pumps, companies can reduce energy consumption in the cleaning process, thereby reducing production costs.

Comparison between high-temperature heat pumps and traditional heating methods

Assume that a toothpaste manufacturer needs to heat 60°C wastewater to 90°C through a high-temperature heat pump with a flow rate of 5 tons/hour. We have calculated that the high-temperature heat pump needs to consume 39 kW of electricity to provide the required heat. If traditional coal-fired boilers or electric heating methods are used, the calculated required heat energy and costs will be significantly higher than high-temperature heat pumps.

Comparison of traditional coal-fired boilers

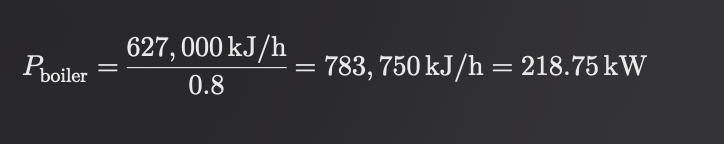

Assuming that the efficiency of traditional coal-fired boilers is 80%, in order to provide the same amount of heat, the required heat of the coal-fired boiler is:

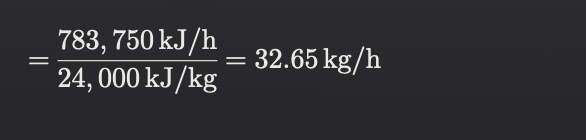

Assuming that the price of coal is 0.8 yuan/kg and the calorific value of coal is 24 MJ/kg, the amount of coal required per hour is:

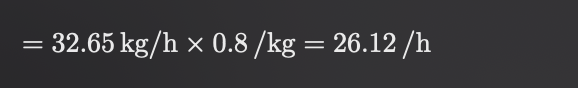

The cost of coal per hour is:

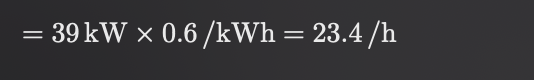

The cost of high-temperature heat pumps

Assuming that the electricity price is 0.6 yuan/kWh, the electricity cost of high-temperature heat pumps is:

Conclusion: Advantages of high-temperature heat pumps in toothpaste production

By recovering the waste heat of wastewater in the production process and using high-temperature heat pumps to heat it to the temperature required by the process, toothpaste manufacturers can achieve significant energy-saving effects. Compared with traditional coal-fired boilers, high-temperature heat pumps can not only significantly reduce energy consumption and operating costs, but also effectively reduce carbon emissions, which meets the needs of green production and sustainable development.

In general, the Application of high-temperature heat pumps in toothpaste production has the following advantages:

- Energy saving and high efficiency: High-temperature heat pumps can recover low-grade waste heat and raise it to the required high temperature, reducing dependence on external energy.

- Environmental protection and emission reduction: Compared with traditional coal-fired boilers, the use of high-temperature heat pumps can reduce the emission of carbon dioxide and other pollutants.

- Cost savings: The operating cost of high-temperature heat pumps is lower than that of traditional boiler systems, and long-term use can significantly reduce production costs.

High-temperature heat pumps are an important tool for toothpaste manufacturers to achieve green production and improve economic benefits.